D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

Clutch stuck with lever forward toward engine or back toward seat?

Just reading that you shut off engine to shift the winch out of gear makes me think your clutch was stuck engaged/lever back toward seat.

How hard did you push on the lever to try to disengage the clutch? Did the lever move at all.....move a lot? How hard is it to pull clutch lever back and snap clutch in? Is there a lot of slack and lost motion in the clutch linkage?

D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

You need someone that has looked inside a D4. I have been in a lot of hand clutches but not a D4.

If i understand,,,,,,,,,,,,, you could not get clutch to disengage and stop the winch turning or shift transmission into gear even though the lever was against the front of the slot in the floor plate and when you looked inside the release/throwout bearing was full to the rear against the clutch brake.

Or ..................things were positioned as above and the lever was stuck (felt like it was hitting something hard?) and you could not pull it back and make the winch turn?

Not an oil clutch model I don't think?

Do you keep the oil cup for the clutch throwout/release bearing full? Does the cup have a standpipe in the center with a wick hanging out of it or is it just a funnel shaped cup that channels oil into a reservoir with a metering pad on top of the release bearing carrier down below. I think this is how the sliding surfaces get lubed

Has the clutch shaft pilot bearing in the flywheel been greased lately? If this is going out it may have locked and has unlocked temporarily.

D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

no the handle was forward and the transmission brake was touching. the winch was not turning and the tractor was just sitting idling. i could slip it into and out of every gear . i shut the engine off just so i could look inside safely. dry clutch and properly lubed and adjusted.

correct i could not pull the lever back. as far as i know the pilot bearing is ok. if the pilot was frozen wouldn't the transmission input shaft keep turning? the input shaft was free except for the drag from the transmission brake.

Sounds like similar to my twenty.The little short links may be worn enough in the holes and pins to get one inside out and jam. Go back in there with clutch disengaged engine stopped and poke at the links a bit and see if one goes too far and jams in. Flick it out again and all works again. Not sure if a D4 works the same. Made new links for the twenty, pins were not worn. Is the clutch adjustment correct?

I think in the twenty all three would fall inwards and nothing looked wrong on first glance. cheers WF

D46U straight blade,D46U cat angle blade,allis chalmers AD4 grader and Khoering 404 dragline. D4C 40A,D4 2T and scraper.

links and pins are good to go. puzzled

Hi Team,

sounds to be like what Wimmera Farmer described in that the over centre links moved the cams inwards to an inner over centre position when the clutch was fully disengaged, then the throw out sliding collar will not go back to the forward engaged position until the links can be coaxed back outwards again. The links/cams should always be posed outwards.

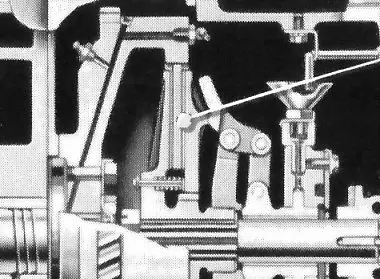

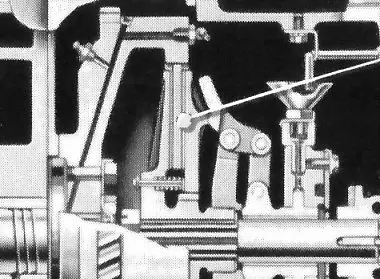

Scan shows correct relationship of the clutch cam lock system components.

Likely lost motion--wear-- in the links and/or wear to the throw out collar on its actuating flange which allows the sliding collar to move too far back and so the links drop inwards and the cams fall back over center, jamming the throw out sliding collar back in the disengage position further than was designed.

Cheers,

Eddie B.