Yes, it does sort of work like a sprag clutch.

There should only be one gasket.

Lubrication is light oil (no grease)

Needs to be clean with no wear to work properly (can be temperamental)

I would not expect the position control to be problem with achieving full speed. Usually the problem is that it won't hold position.

There are several adjustment/measurements to setting the governor linkage, have you checked those?

What's your engine s/n? Later units added a clamp around the clutch housing.

Sounds almost the same as mine in My D7. It is running a 3306 tho. I can attach some photos of the D7 set up may help. It has everything but the wave washer? I found mine wouldn’t get full throttle until I set all 3 levers as the manual said. But that is after you have the unit back together. I think you D8 might be significantly different tho. Let me know. I have only just rebuilt my thottle and Gov assembly about four days ago. Pretty fresh in my mind.

[quote="halfcirclej"]I took my linkage and mechanical parts off to put new bearings and seals in the assembly.

I can't find any information on rebuilding this unit. I was able to order the seals and bearings, gasket 1 each. However, during disassemble there were 2 gaskets installed?

What I need to know what to lube it with when I reassemble?

It has two rollars, 2 springs for the rollers, one spring that goes between the two halfs, and a wave washer in back of throttle piece.

The problem was I couldn't get full RPM of the engine.

I think it operates like a sprag clutch??? The parts inside doesn't look worn, no flat spots, the only part that looks worn is the wave washer and bearings. The gap between the pin doesn't have much room to move, I fugure it's equivalent to the .800 inch movement of the rack in the pump.

This is just my theory of operations.

Any thoughts on this project will be appreciated of all with knowledge of this piece.

Thanks Mitch[/quote]

The engine was working well the last time I operated the dozer. Went home had a reverse shoulder operation. I went back to the farm after rehab an physical thearpy. Hopped on the dozer and if felt like it was producing only half horse power. Took 3 attempts to push over a tree. Befor I was pushing over trees 3 times as large. Just feels like no horse power. I've purchased a new diaphram for the air ratio valve. I have read it will not reach rpm if bolt doesn't let the rack move to full rpm.

Serial 77v126xx, engine 17S13665, arrangement 7N3491 for info. 1979 year mfg.

I plan to put back together linkage and measure all connecting rods per service manual. Doesn't have the rack setting information, manual states to see it but I do not have it. The manual cost nearly $600.00, dog gone high dollar book. Then give it a go. Then if ok, I'll skip the air ratio rebuild, if not that will be the next thing I will tackle being careful to count the threads on the bolt. Next????? Call a Cat man that is older than me, ha.

To all that replied, thank you very much I appreciate the info.

I really not a new member but I had to put a new pass word in, to get on site again. It would not let me correct it nor put my email in. Will try it again tonite. No inter net no cable just a tab and smart phone.

thanks again Mitch.

I have the rack setting info if/when you need it. Are you getting full rack travel?

That engine s/n should have the band clamp around the cover. As tc says it is some sort of stop that may require adjustment.

Hi Team,

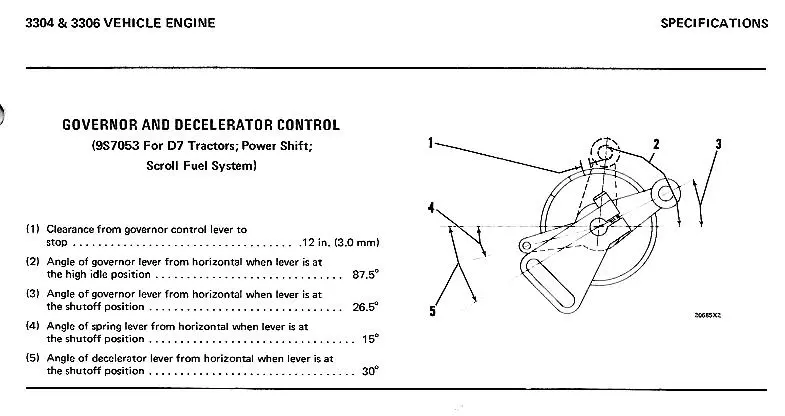

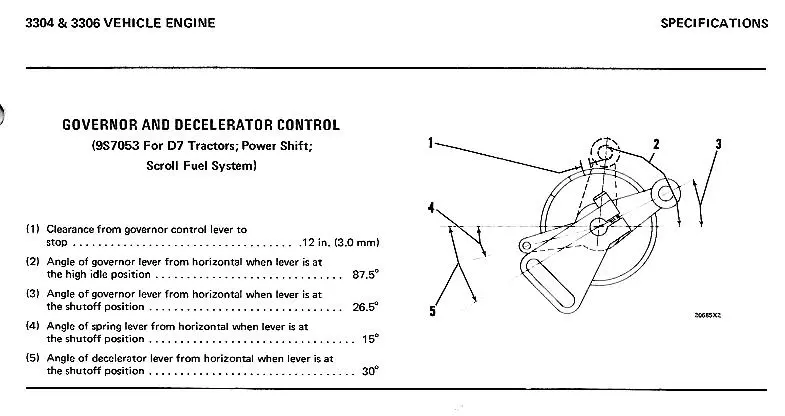

here is a scan from a 3306 Vehicular Engine Specs. Book.

Yes, it is a D7F and not a D8K but from memory they are same style of set up and I have added the scan as an example of what you are trying to achieve as a stop clearance when at Full Rack/High Idle.

From memory the Stop is a clamp arrangement that can be loosened and slid around the housing it is mounted to.

At Full Rack/High Idle there should be 0.12" clearance, at Point 1, between the Stop and the Rack Control Lever.

Sir, the photo doesn’t look like the assembly on the D8K

That I have, it doesn’t have the slotted looking part.

I like the degree things though.

I had to order more parts this morning, they skipped a bearing. Decided to go ahead and

order the 3 springs inside the mechanism also. The parts manual states 2 gaskets are used???

It had 2 gaskets when I disassembled, however, it was very sloppy with lots of end play? I didn’t like that much? I assembled with one gasket to see if end play disappeared, felt much better. I think ole magnet is right. The parts manual must be incorrect. So it will be a few more days before the parts come in and I will let you ‘all know how it comes out.

I appreciate the feedback.

Mitch

My Parts Book shows 17S5317-up using one 7M6955 gasket. 17S14472-up uses two gaskets.

Hello again D8K specialist, I have replaced all bearings, springs, and seals in both the left mounts and right sides of the decelerator. Moving the input side on the bench does not result in a movement on the output shaft to the right side shaft,(govenor/pump) until the pin on the input shaft contacts the gap on the output shaft??? Have not installed on tractor yet.

I cannot get in my mind how this piece functions yet??? Do the rollars work from the input side shaft or do they function from the output shaft side??? My thoughts are the govenor has something to do with it or the decell pedal has a function to move the govenor to idle, ok, that is what it does directly as it is connected to the govenor rod. What action in the decel assembly happens, and what action happens when the decell pedal is released? Does the govenor push the decell assembly back to the throttle set position?

I guess I'm looking for a theroy of operation or function. I will be back at the farm in a few days and finish the reinstall on the tractor.

Any one know the theroy of decel function and how it operates inside the assembly??

Thanks fellows if anyone can enlighten my old brain