I was not aware the 12F still had the knuckle buster type pcu. The schematic doesn't really match up with the picture of the actual control.

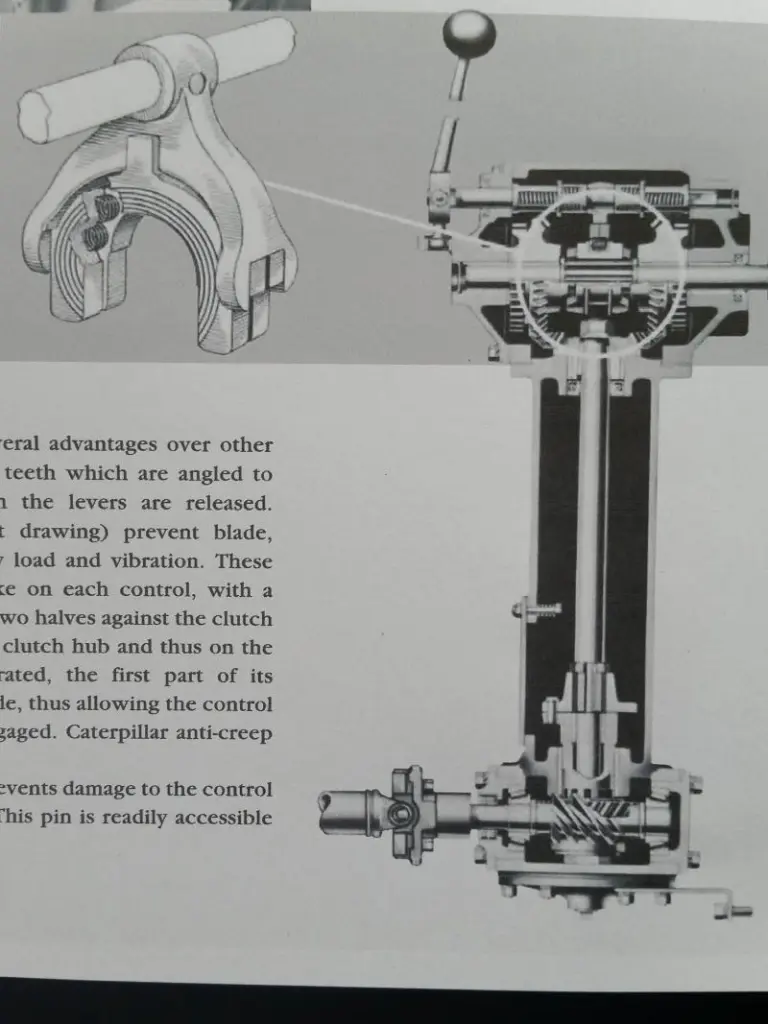

If ..........IF .....the 12F has an improved version of the dog clutch pcu as shown in the diagram. The power is transmitted up the vertical shaft to the primary horizontal shaft that will be the side shift I think. From there power is transmitted to the functions on the outer shafts by gears meshing with the gears on the primary shaft. There should be no keys to shear etc as each set of gears (one in the front and one in the rear) rotates on the respective horizontal shaft with bushings. First shaft on the left beside the side shift (primary) horizontal shaft would be the circle reverse so it makes sense that running it into the wing support post would cause damage in the correct spot(s) ??????

One question I have is will the inoperable functions work in the opposite direction or are they completely dead? Seems like you would have had to break both front and rear gears on a shaft to disable the function in both directions .......both up and down on the left end blade control for example.

The mention of a pressure relief makes me question whether this control is all hydraulic and the schematic is not applicable.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Tommyrbk.

Sorry, I can't help as that is one model too late for me. I have been into several control boxes on earlier models but never into a 12F or the 14E which has the same type of control set-up.

Ccjersey's answers do make sense though. If it was the shear pin at the bottom of the vertical shaft, you would have no response in the controls at all.

Just my 0.02.

Looking at some pics of other 12f graders, I see some kind of hydraulic motor lifting the blade. Hydraulic motors and rams doing most other chores. Definitely not mechanical. My experience is with old cats and 120g and later.

What series 12 F?

12F's can be either hydraulic Disc-Type Clutch Power Control with mechanical relief valve limits or

Hydraulic Jaw-Type Clutch Power Control with mechanical relief valves on the circle controls and solenoid operated relief valves on the blade lift functions. The electrical circuits are fuse protected. To reset the lift function you need to hold the reset switch depressed and push the lift control lever to move the lift arm away from the stop.

Come back with the system you have.

[quote="Old Magnet"]What series 12 F?

12F's can be either hydraulic Disc-Type Clutch Power Control with mechanical relief valve limits or

Hydraulic Jaw-Type Clutch Power Control with mechanical relief valves on the circle controls and solenoid operated relief valves on the blade lift functions. The electrical circuits are fuse protected. To reset the lift function you need to hold the reset switch depressed and push the lift control lever to move the lift arm away from the stop.

Come back with the system you have.[/quote]

Thanks for the help, It was the pressure relief valve with a bad o-ring. All good now, swapped them left to right to see it that was the problem. Added one washer and new o-ring. Moved a lot of snow all afternoon. Just need to change the Wing support post some how. Probably easier to get a different machine 😊

You don't need to change the post, just your thinking. It will become natural that you don't turn as far to the right as the left. Plowed a lot of snow with a #12 and the same style wing post. Only nudge it once a year or so at the beginning of the season.

no need to change your set up. even new graders can still hurt them self. i know the city got a new JD one and you can still hit your self with the blade as they have. the cab is not new anymore is all i say .

You have a wonderful day. Best wishes. Deas Plant.