Reply to Oldcarman:

Eddie B,

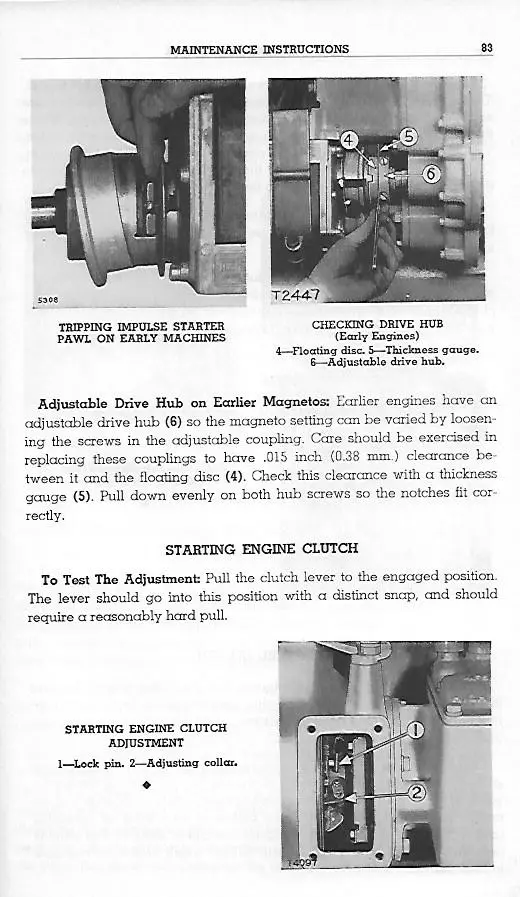

Thanks much for scanning the books for me. The info seems to be somewhat different than the D8 2U I am working on. I think that the timing mark (from service manual) is via a pipe plug just above the Bosch Mag. I guess I still don't know which is officially #1 and which is #2 cylinder, but it's timed now and was firing well on both cylinders. I don't recall that inspection plate for TDC marks under a cover either. I need to look though.

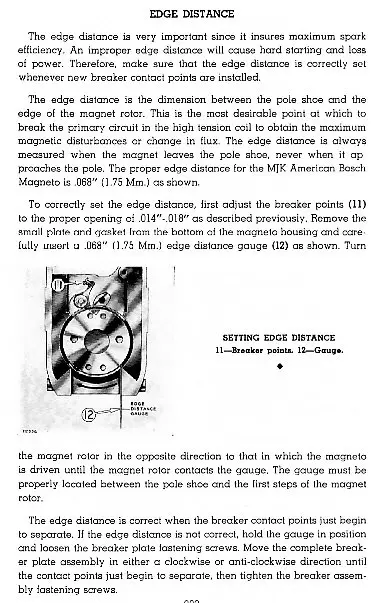

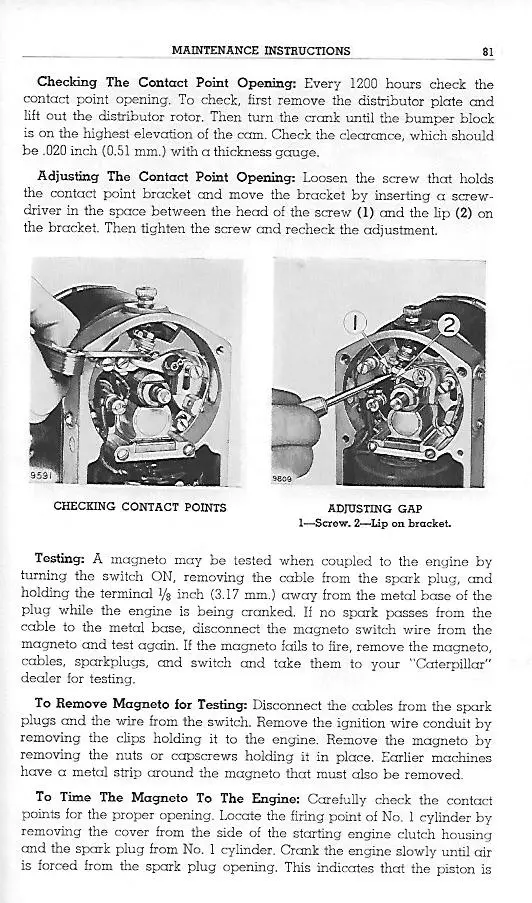

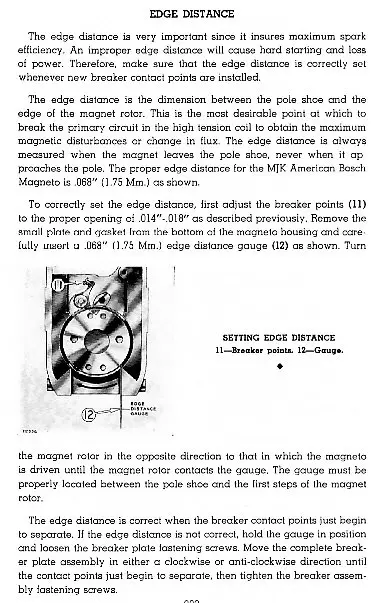

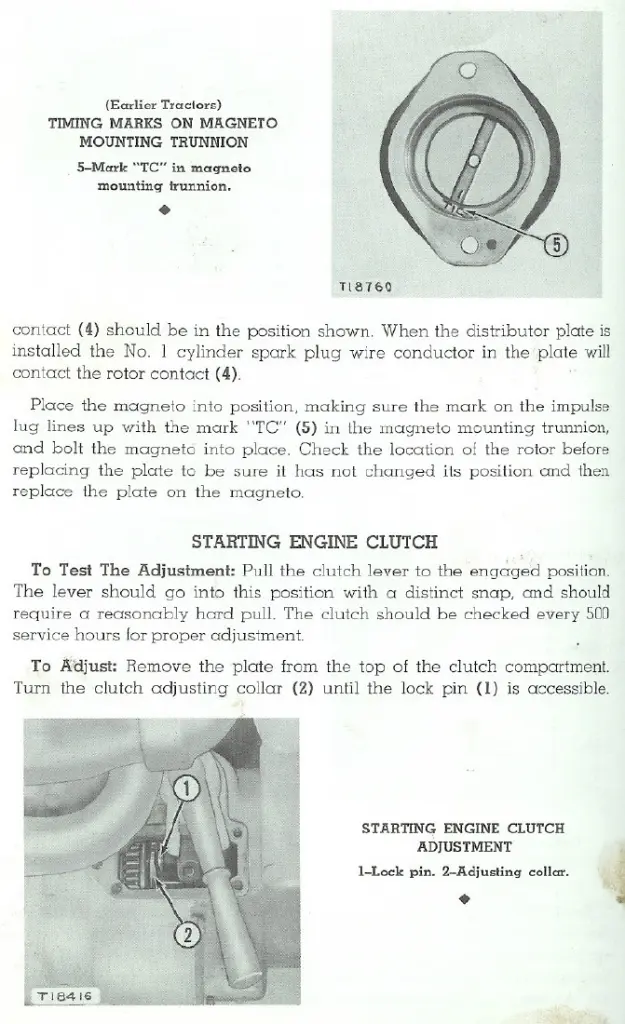

After digging into this MJK 180 and also deep into a MJK 360 for the DW10 , it seems to me that the Cat service lit seems to talk a lot about the breaker point gap, but the edge gap seems more important. On the MJK 360, I set the points at .014" using a dial test indicator and I could not get the edge gap set even when rotating the breaker plate as much as possible. I re-adjusted the points out to closer to .020" and then I could get the edge gap set to .068-.075 or so. I think that the edge gap is much more important than the point gap. Also, I cringe when I see pictures of an oily feeler gauge going in between two nicely cleaned or new breaker points.

Thanks again Eddie. Ill study the pages and see what I was supposed to do.....

Hi Team,

GREAT job getting the pony running for your friend to see and hear again.

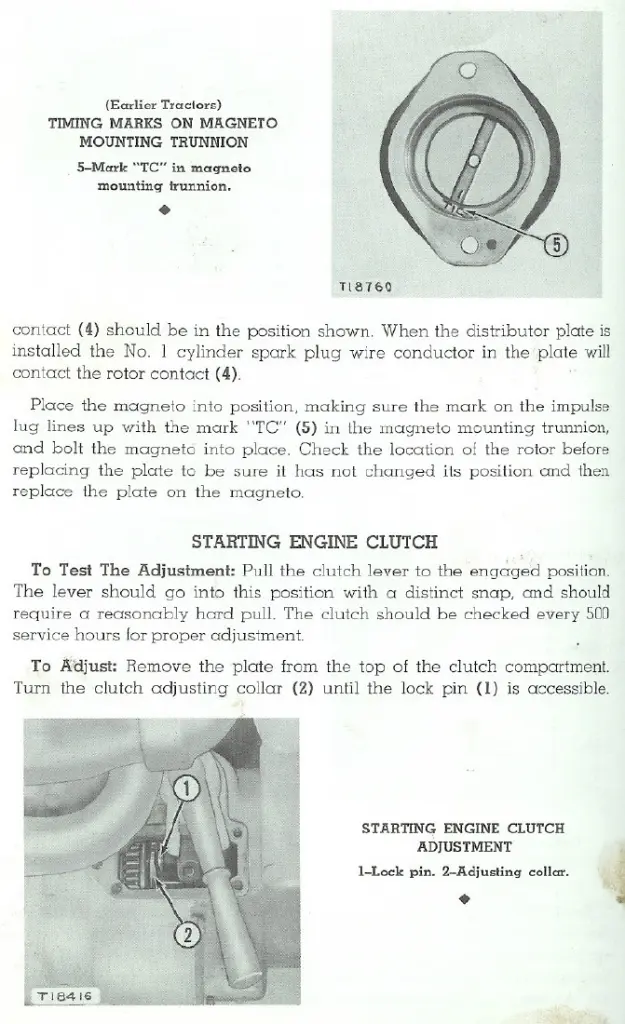

My thoughts--the edge gap helps set the magneto rotor in the optimum spark producing position==most magnetic lines of force cut by the rotor==I usually turn the mag as slow as I can by hand and adjust the edge gap adjustment for the best spark with the least speed--often I find the edge gap measurements are not the best spark generating position.

I usually screw a piece of welding wire to the mag body by one of the distributor cap screws and adjust its end to be around 1/16" to 1/8" from the coil copper connector strip to keep a constant gap--as i zero in on best spark I will usually open the gap to 1/8''

I run my magneto spark plugs with around 0.020" gap to be kind to the coil, cap, etc.

No 1 pony cylinder I believe is the forward cylinder as in the big engine.

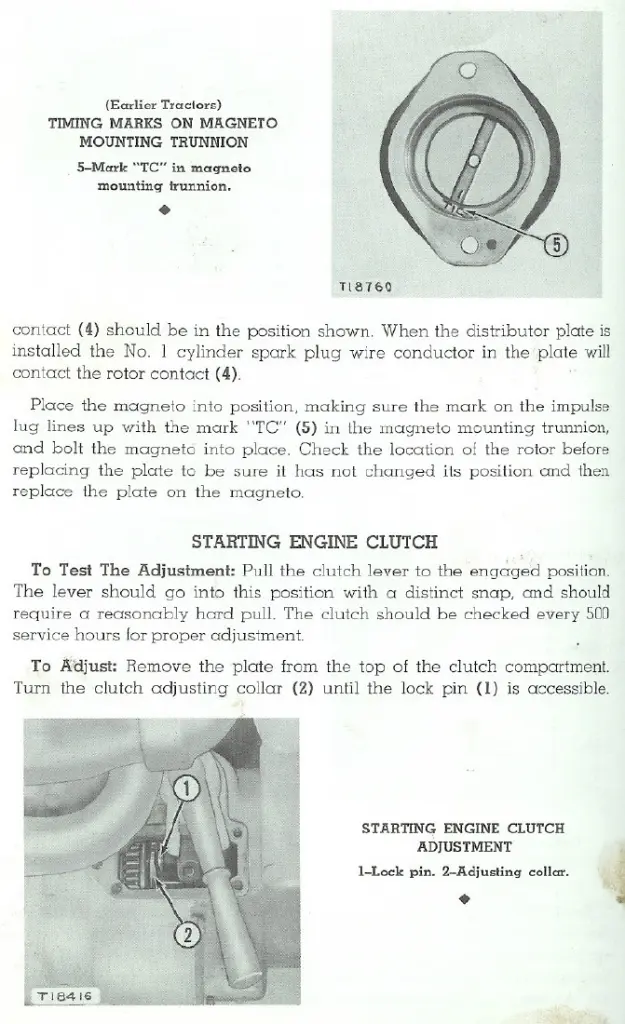

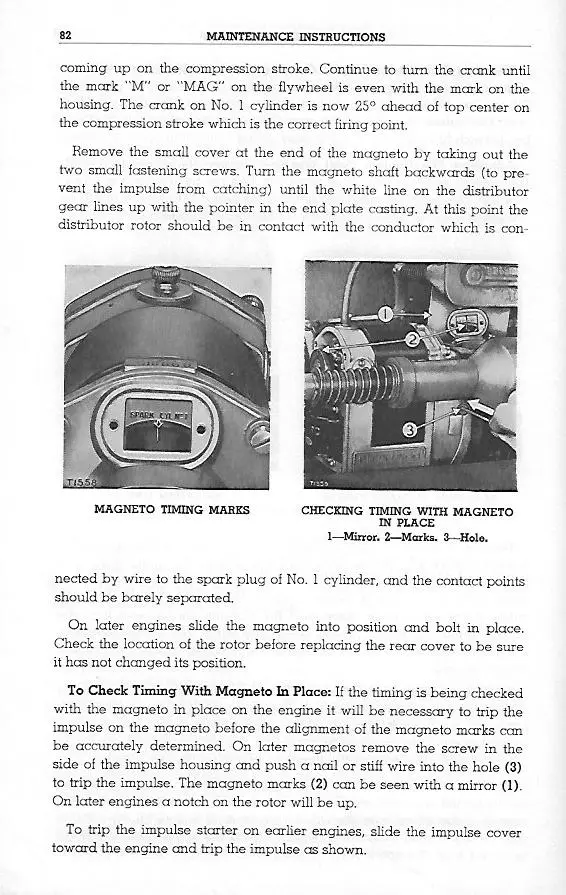

I see the side plate on your pony clutch housing for locate the timing line on the case mid way in the forward side of the opening. The MAG line is on the flywheel as indicated but can be hard to find when covered in rust and/or oily clutch dust.

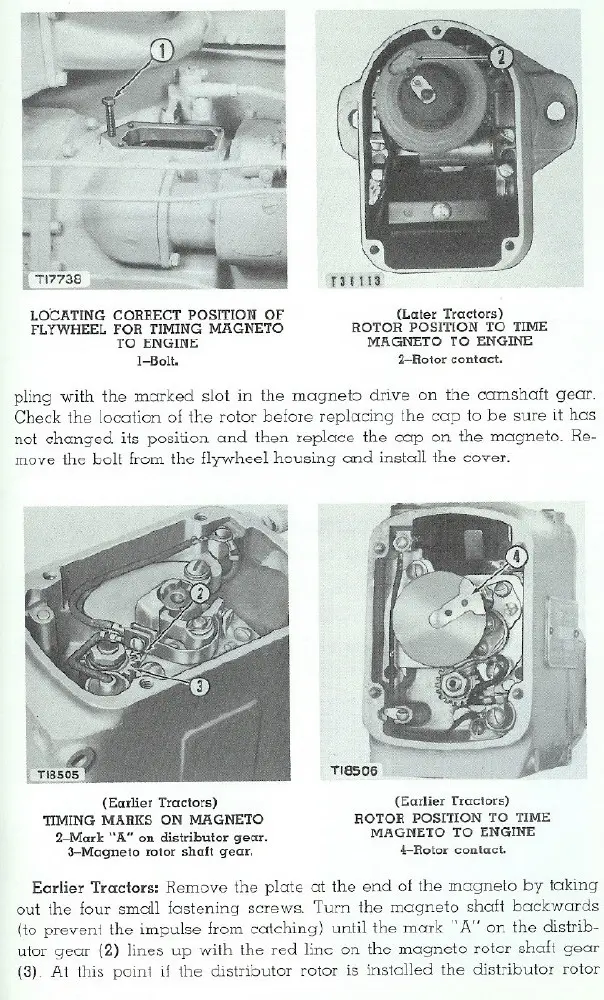

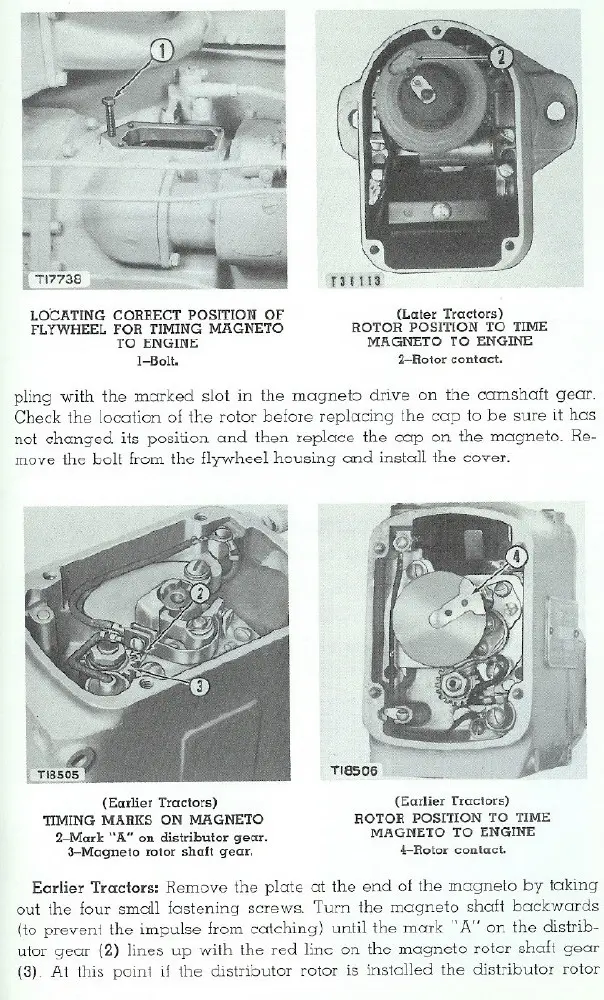

The 17A D7 pony has a top plate on its pony flywheel that via a hole drilled into it a bolt is inserted to match a drilling in the flywheel corresponding to TDC--you have to find the true TDC Firing stroke--compression stroke.

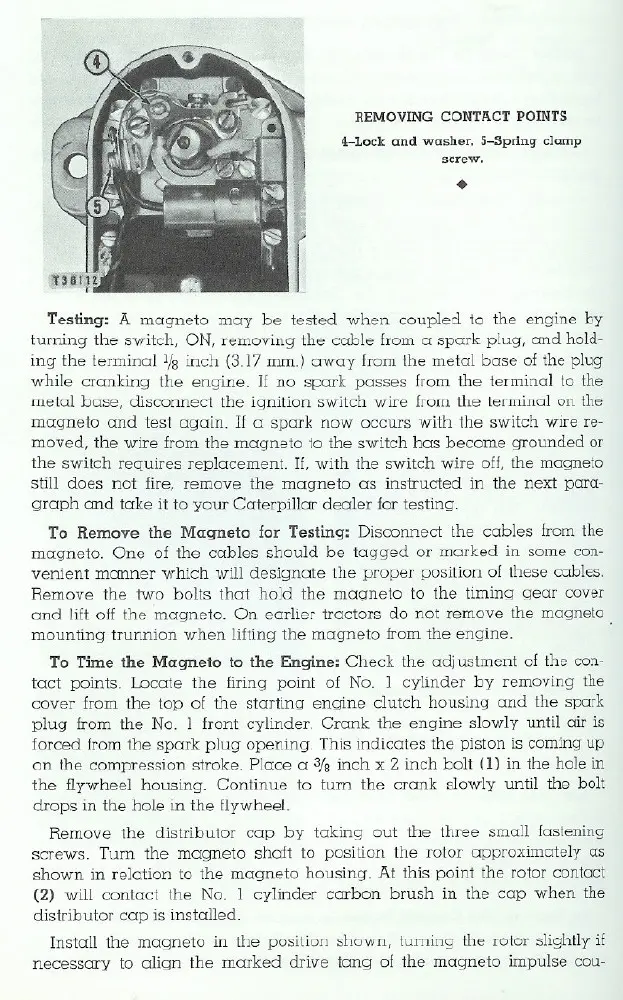

Different models and makes of Magneto have their own individual points gap setting-If the wrong one is used it is well known that the pony will kick back on the second cylinder--especially when starting by hand.

Cheers,

Eddie B.