Sprocket press is 30 Ton so it would take all of that and more to remove.

Pay attention to the spline connection between hub and sprocket. They should not bottom out when pressing.

Information out there that you can put glow plugs in the D3400, D4400, D4600 engines is 100% bogus.

2000CCA battery capacity should be more than enough to crank the D4600 even on twelve volt. What is the condition of the starter and are you sure the starter pinion is not running to tight on the ring gear?

Batteries go where ever you can find room, usually have to be fender mounted if your running both pony and DE start.

Blade speed seems about right.

Hi Phil,

have you checked your final drive bearing adjustment--you MAY get away with it if the bearings are slack--tightening them realigns the seal rubbing surfaces and if you are lucky can stop the leak.

If it is only the outer seal leaking you may get some more time just replacing that one--original bellows for these were brass and known to fatigue fail in the bellows folds.

Are you sure the starter helix gear teeth are the correct cut from memory they can be left or right cut/angled and so they jam in the ring gear teeth if wrong and so are slow turning due to interference loads.

Cheers,

Eddie B.

Thanks for the replies.

Old Magnet, I thought that was the case with the D4600 and I was sure I read a thread on ACMOC about it but could not find it. I don't know how effective a glow plug in the intake manifold would be. There are some I have seen that have a glow plug at each manifold port in the head that might be more effective. By "Pay attention to the spline connection between hub and sprocket. They should not bottom out when pressing." do you mean make sure the sprocket is pulled off square and even to prevent damage to the shaft/hub?

The starter meshes perfectly with the ring gear. It is the correct cut helix. The starter motor is very old and may have lost some efficiency. I did get an auto electrician to go over it and I believe he changed the brushes and the solenoid but that is all. It does not sound very healthy when starting. If the 24v starter would start the engine with smaller batteries then they would fit on the fender. What sort of CCA's would be required with a good 24v starter?

Eddie thanks for the tip about the sprocket bearing adjustment. I hope it is that simple but as this machine has been sitting for around 40 years I doubt I will be that lucky😊 The oil is inside the track so I assume it is the inner seal that is leaking. There is no oil running down the outer face of the sprocket.

Regards

Phil

Seems you have a tuckered out starter.

Same 1000 CCA batteries, just rigged in series instead of parallel.

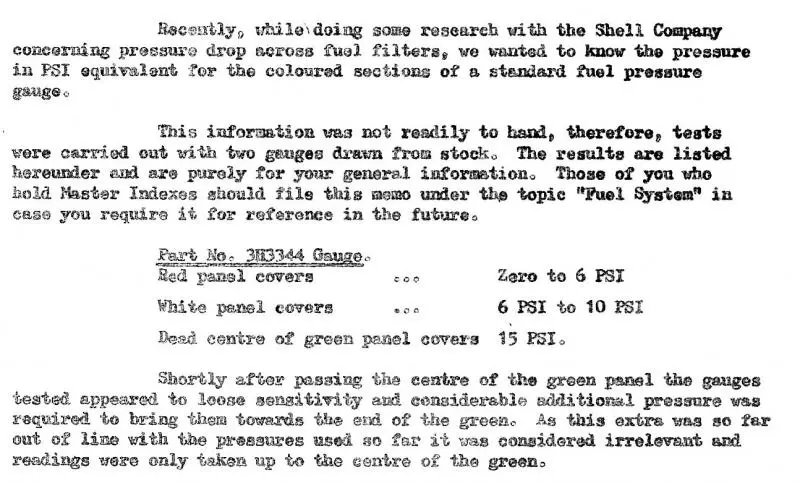

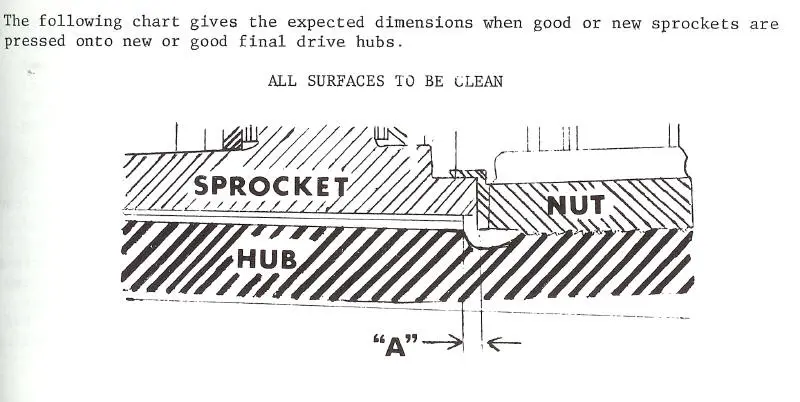

Sprocket to hub spline fit should be "A" = 0.09" - 0.16" when pressed.

Hi Phil,

alas, when these machines sit that long it is not unknown for the cork seal ring to adhere to its steel counterpart and tear when first moved. Sometimes--rarely-- they can heal up if the tear was not too severe.

Fingers Crossed for you.

Cheers,

Eddie B.

Thanks for the info Old Magnet. The starter does not sound good when its turning the main engine. I have been cheating a little. Rather than use the pullrope on the pony I engage the starter pinion, turn the main engine over with the starter and engage the starting engine clutch lever which starts the pony motor😊

Eddie

I cannot see an oil trail when using the machine only when it sits for some time can oil be seen leaking. About a cup of oil leaks out over twenty four hours and slows or stops.

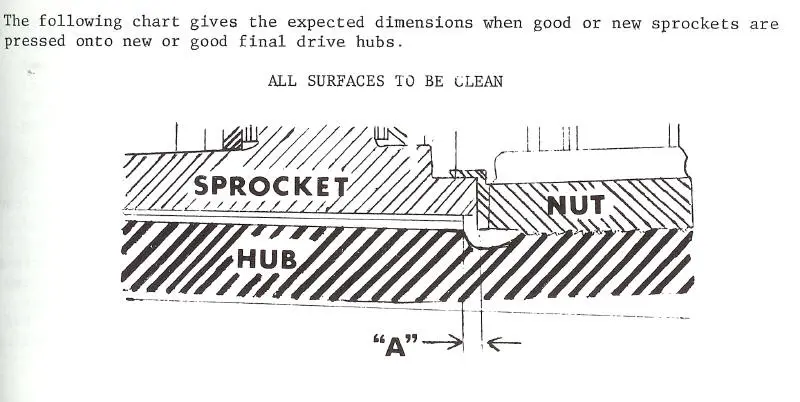

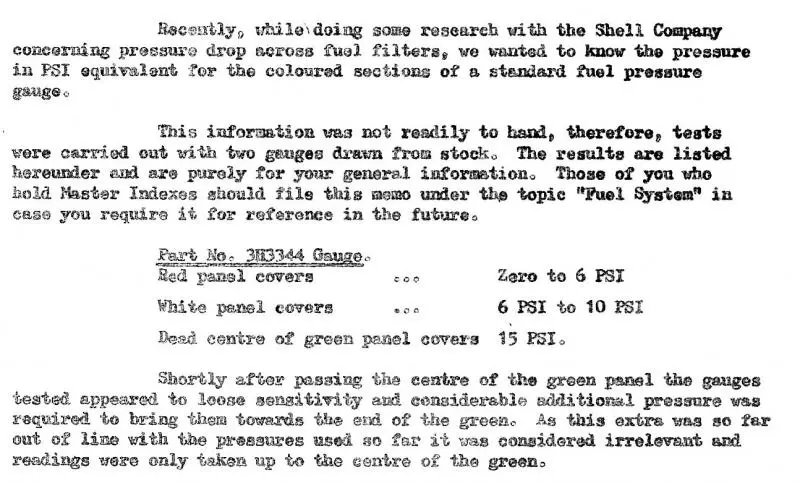

Does anyone know what the fuel pressure should be when running? I am only getting about 12PSI. I used the 266-0889 gauge and it does not leave the red.

Regards

Phil

Normal operating fuel pressure is 15 psi, 12 psi is good.

Hi Team,

just to add to the thread for interest sake, data is from tests done at our Dealership as outlined.

Cheers,

Eddie B.