yep, comes out the top. pretty straight forward. you'll need a tractor loader or block and tackle to lift it out if you're by yourself.

I have changed many tractor clutches and split big ones. So for fairly exoerienced mechanic how long of a job?

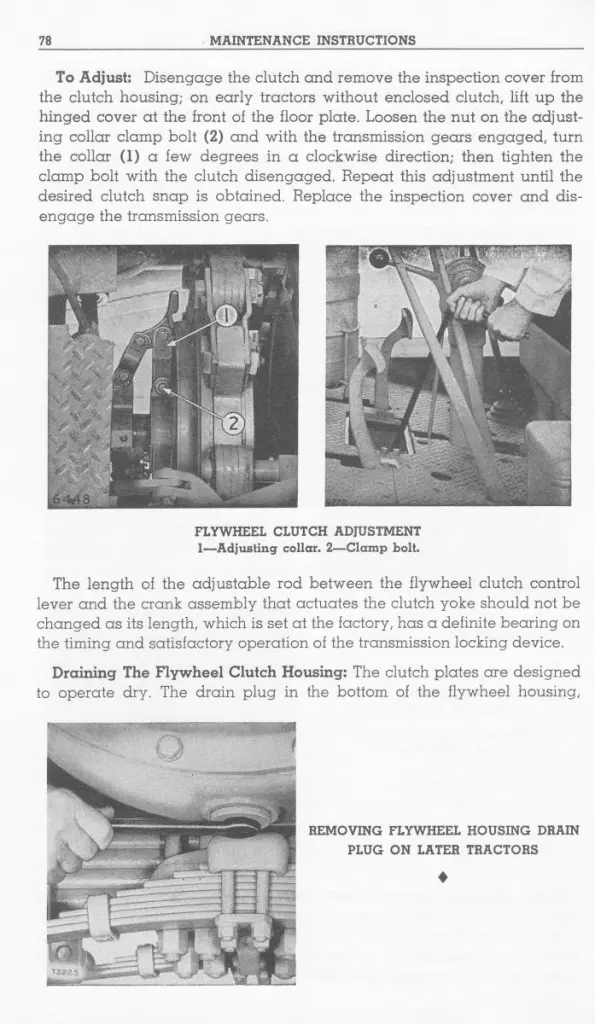

The fibre discs are not very thick . you should try adjusting the clutch before attempting and repair as this will most likely solve your problem .

Clutch adjustment and lubrication is part of the operators daily routine.

thanks. I have not bought it yet and so dont have a manual. Can anyone tell me briefly how to do so? WHen i looked it did not look like there was room for more adjustment but I may have been looking wrong.

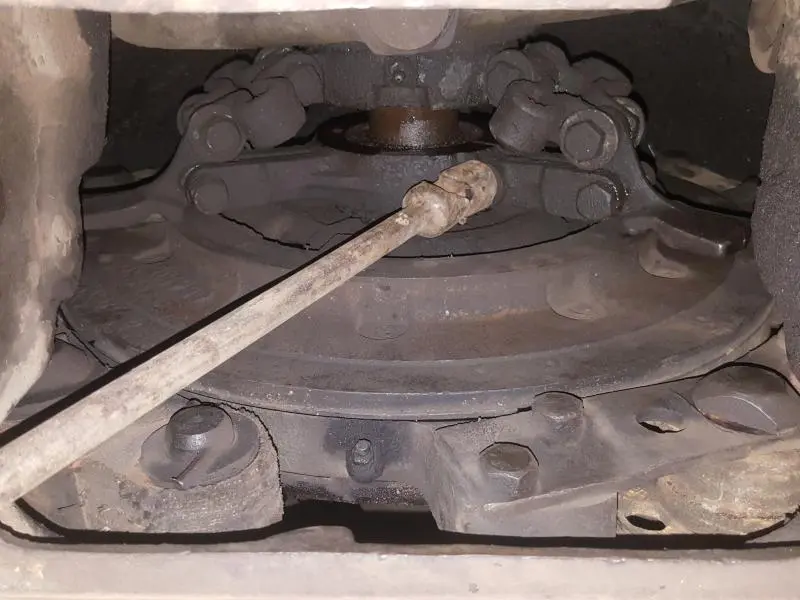

Take cover off inspection hole and loosen bolt on adjustment collar, turn clockwise till you get a snap in clutch lever. If thats unsuccessful and clutch needs to come out remove floor-boards, remove top of clutch housing. disconnect drivelinks, remove 2 drive bolts from flywheel, clutch unbolts from transmission, you'll need something to lift it, these suckers are heavy. scope out the starter drive while you have it apart, never be a better time to repair it. good luck.

Here you go...

[attachment=49752]D7 clutch 4.jpg[/attachment]

I hope this helps,

Craig

Thanks for everyone’s help. Unfortunately I was unable to find a hauler so I did not purchase. If anyone’s looking for a well maintained 3t with 90%uc there is one in Atlanta. I have pics if you want them