Good grief!! Those blade cylinders must be off an 8! That cab looks like its made for driving through buildings for demo work. You dont need to bring the engine down to an idle when shifting from fwd to rev. half throttle is fine.

https://youtu.be/iFlZzZnHHaI

Good grief!! Those blade cylinders must be off an 8! That cab looks like its made for driving through buildings for demo work. You dont need to bring the engine down to an idle when shifting from fwd to rev. half throttle is fine.

https://youtu.be/iFlZzZnHHaI

Hi Rome K/G,thanks for the advice,i was worried about blowing the transmission up if it is still revving.If i have the revs right down and pushing dirt,should the decelerator still work as at the moment it has not affect on revs unless i basically stand on the pedal hard.The decelerator tower idle adjusting bolt is screwed right out as far as it it will go,not sure if it should be screwed in or out as it does'nt say in the manual,when screwed out,the pedal does work more than when screwed in though again, the pedal only really works at high revs.I did try to adjust the low idle bolt on the top of the governor housing but the bolt seems to be under pressure not letting me turn it.Also it revs up and down and idles fine with the hand throttle.

I will check the video out thanks.

The guy i bought the dozer off said it had extra big blade cylinders on it for back in the day a lot of deep drainage was made so the dozer could dig deeper drains.The cab was built i think for land clearing back in the day when bigger trees were pushed and i think it is from manjimup way in the south west where timber was bigger.It definitly looks like a Mad Max machine though.

I bought the dozer to rip limestone rocks out of the ground and tried my first attempt with the ripper yesterday and sucessfully pulled a massive rock out of the ground,they look like small rocks until you start digging.I did notice a crack in one of the ripper support crossbeams which will have to be welded up before anymore rock pulling though.

Just watched the video you mentioned Rome K/G,the dozer is going quick and noticed he did'nt use the decelerator at all,definitly getting the job done.Not sure if i'll be driving that quick,i'll be nursing it as an old machine,the tracks as you can see will have to be replaced sometime when i can afford it.

Hi edb,thanks for your help,i will try to get my decelerator going at lower revs,i figure its the same principal as a car auto transmission,always stop and no revs when going from forward to reverse.

The decelerator tower spring removal i attempted as you said,only take one bolt out first then slide the cover around only enough to expose the centre of the spring,then in the manual it says get a 1/4" -20 NC bolt 2" long which i did but only half thread(all i could get but i will try and get a full thread)i did thread it down half an inch before it would'nt go any more,maybe theres oil sludge down in the thread,i will try and get a full length thread bolt and try again.I just wanted to see if the spring is broken but doubt it as hell of a lot of tension on cover when moving sideways.

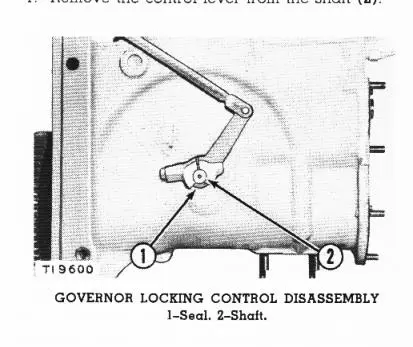

You mentioned about the governor control linkage lever bolt maybe being loose and wear happening,hoping it wasn't that but will check today to see if i can see a loose bolt and play.Do you think the bolt could be replaced without taking the housing off.It looks like too big a job for me to do that.It may be a trip back on a truck again to get it fixed.Are parts easy to get for the old D7e.Finding a mechanic that knows these old machines maybe a problem too.

Thanks again for your help edb.

Like I mentioned just bring the engine rpm down to around half throttle pause in neutral a second then shift to forward or reverse, slowing all the way to idle just wastes fuel when the engine has to spool back up to higher rpm to have power for the load applied, and NEVER idle down when pushing a load and shift from first to second, if so it will just stall or overload the convertor.

Hi John

it is possible/desirable to change the bolt in-situ. Doing just this will improve the looseness/lost motion appreciably--need to orientate the Gov lever for best access, it is reached by coming up from under the housing--old bolt out, new one in, jobs done.

Looks like I confused you by adding about the lever/shaft renewal needs the whole unit out--sorry.

As Rome K/G said you do not need to do a full De-accel. to Low Idle as it wastes time, fuel etc. and the reason Cat had a spec range for the D-accel. RPM's that is above Low Idle.

From memory now I am sure we used to adjust them to around the upper spec. of 700 RPM--actually I feel the shift is smoother and quicker at that.

Cheers,

Eddie B.

Hi John,

Hi idle for your tractor if I remember right is about 1200 rpm, when changing direction you only have to drop the revs enough to take the shock/jolt out of the change, make it more of a fluid change of direction, many times you only have to drop the revs maybe 200/300 revs. Timing is everything, with practice it will become a natural thing that you just take enough off to get that smooth fluid change. The tractor should not labour from low revs to get going again, nor should it jolt. It is hard to describe, if you can see someone doing it would help you a lot.

All the best with the tractor, looks like a nice 160hp E, the canopy looks a lot like a forest dept job to me.

Regards, Wombat

Hi All,thanks for your help,i had another go with the dozer today and checked out the linkages,they are pretty sloppy,i guess a well used machine.The hand throttle although loose still works good,Eddie,i never thought to replace the bolt from under the gov housing and will have another look and appreciate the help.I fired the machine up again today and the decelerator did work at higher revs although that was with pushing my foot very hard on the pedal,at lower revs,nothing unless i stood up and put a lot of force on the pedal(probably not a good practice to drive while standing up),i looked at the linkages again and the linkage attached to the decelerator tower housing moves about nearly 2 inches before it actually starts working,by then the foot pedal is too far down and hard to use.I guess the internal workings are well worn and need replacing.I did think of a short term fix as to maybe making a shorter linkage to the one in the pic so as the pedal would be more raised and easier to use,not sure if it will work but i am after more control at lower revs as i have many trees etc to negotiate around.Not sure if that is just achieved by using the hand throttle alone.

Rome K/G,i will take your advice and pause in neutral before direction changes,i have been practicing today although sometimes hard to find neutral,sometimes only forward or reverse and did happen on my first drive,had to shut the throttle otherwise demolish a shed.I hope that isn't a sign of more problems,fluid is full,but i guess it is an old machine.My tacho is not working so not sure of revs but that is on my fix list.

Hi Wombat,i am definitely still learning to drive the D7,twice the size of my 933 in bits,think i need plenty of practice.I do not have much info about the dozers life but,i think you are right,it has a heavy duty cab so definitely used in the South West of Australia for forestry,it did have a tree nudge bar attached to it at sometime in its life going by the weld marks on the blade support bars.

Appreciate everyone's help,i'm learning a lot,i plan to restore the D7 to its former glory,cheers John.