Reply to Old Magnet:

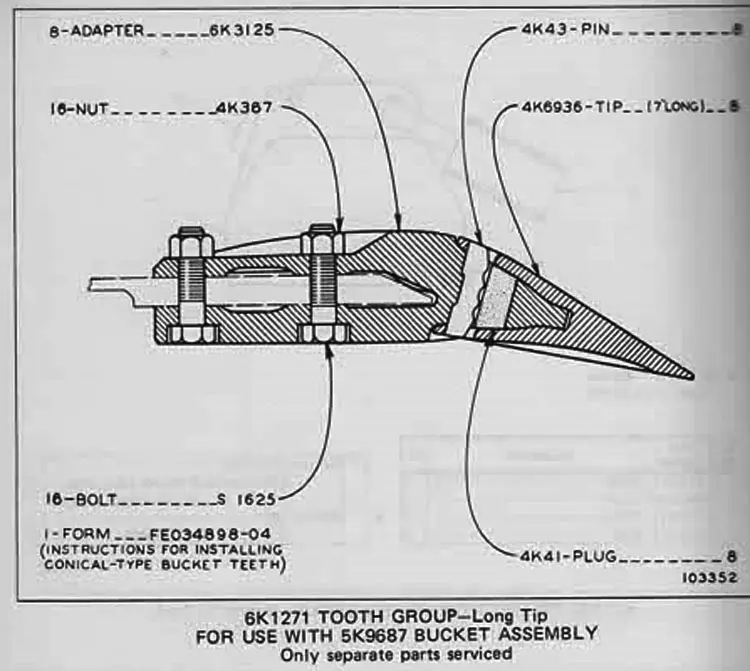

Closest I could find for a 3/4 " thick cutting edge bolt on side pinned adapter is a #9J4207. It is for a 2.62" edge depth and a 3.5" 5/8" bolt spacing. Uses a #1U3202 long tip. Actually used on 931, 935, 910, loaders

Thanks guys for all the info. Good stuff and much appreciated.

I have some add'l info that maybe some of you could comment on.

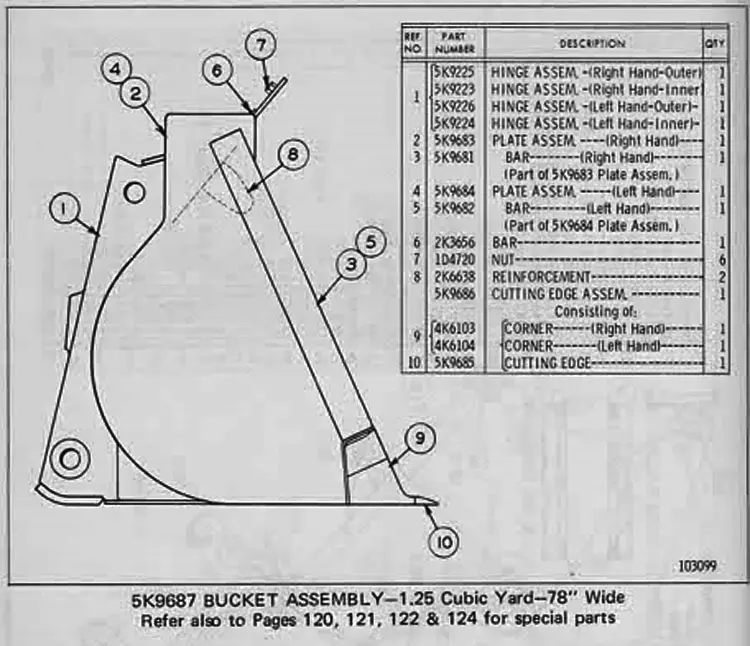

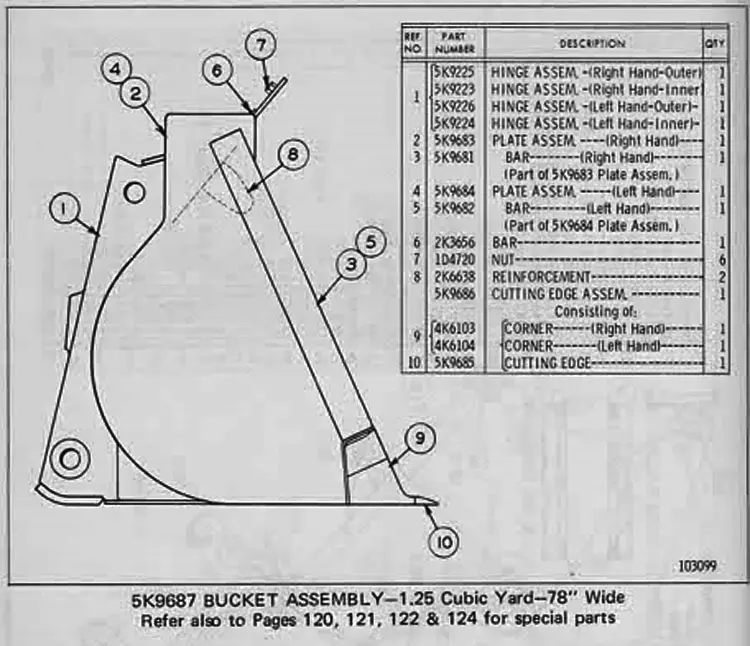

The bucket is 77" wide (inside dimension).

The holes in the bucket are 1" diameter!

Center to center of holes is 5" apart!

And from the front edge of the bucket to the first bolt hole is 1".

I have not been able to find anything that even remotely fits this bolt hole pattern (5" from center to center) and bolt hole size (1"). idk if the previous owner adapted this bucket for something else or what.... so i'm looking to improvise to get teeth on this guy.

and after doing some research...I believe Old Magnets suggested adapter and teeth might just work.

On the 9J4207 Adapter: I need to find out how far back the first bolt hole is from the tip of the inside cutout/slot for the bucket to the center of that bolt hole in the adapter. (is there a drwg w/ dimensions on this anywhere? I haven't been successful finding it)

If adapter will accommodate the thickness of my bucket to slip in the slot of the adapter and the first bolt hole of the adapter lines up w/ my first bucket hole that is 1" back from the edge of the bucket, I think I'm good. That way I can get that first bolt hole in. From there, I believe I can weld the rest of the adapter in place of the second bolt. Then I can buy the teeth to fit the adapter....and i'm good to go.

thoughts??

thanks for all input!

Cheers!

JR

ps - spent the day rebuilding the seat bottom (wood was completely rotted and gone) , securing the batteries (they were just hanging out in the compartment) and trying to locate and grease the fittings I could find!