Usual process is to swap injectors first on a suspect cylinder but in this case it looks like the one pump is off. Some have a pin marking the timing on the gear and some just have a notch. Check to see that the part numbers match on the pumps or get the numbers so we can check if they are compatible.

The governor certainly can be sluggish and unresponsive. I ran a 9U that was that way for a long time. I didn't realize it was abnormal until we got another one. Then I realized how it should have been with the ability to turn and maneuver at idle speed and have the governor respond and prevent stalling. Same for operating at full throttle pushing with the dozer.......you didn't have to keep your hand on the clutch to keep from killing it if you hit a root or stump, the governor would respond and it would spin the tracks!

One thing to check first is that the injection pump housing is full of clean oil up to the level of the oil fill on the side. Might want to drain the governor housing first and remove the injection pump side cover to check that the rack moves easily front to back and spray it with penetrating oil if it does not. Beyond that you get into the governor where you can have seized bearings and bushings with pins through them that are stiff or worn so there is lost motion or flat spots worn on rollers etc. It is a simple mechanism, but it needs to be in good shape to respond correctly. The governor is splash lubricated from the oil it shares with the injection pump housing.

CCjersey - that's exactly how this tractor is acting. I came up on a dry dirt pile today and before I could react - it died. Nice little hike to go get my pony battery......

Rack in injector system moves freely, new oil. I will pull the cover on the governor and see what falls out.

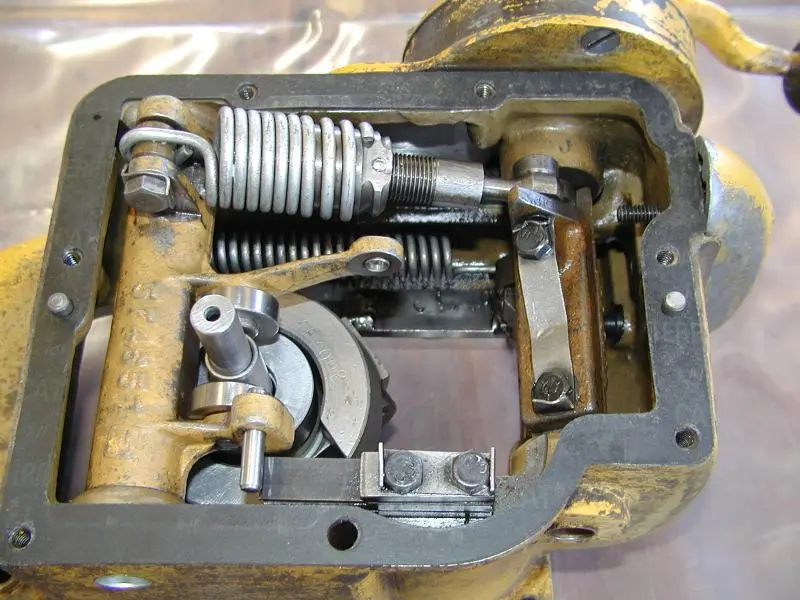

Ok, pulled the back cover off the governor and nothing fell or ran out of there.

I know nothing about this governor - but one thing that caught my eye😖hocked: was the adjustment on the main (?) spring. It seems the spring is extended quite a ways. Should the spring be under tension or compression when at the idle position ?

Although the spring collar is threaded, I see a pin in the collar which I assume locks it in place.

So, for those of you who know - or have seen this spring before, does this look normal ?

As mentioned earlier, my governor does not govern. When I try to climb a hill or push dirt, governor does not react.

Thanks

[attachment=45644]image.jpeg[/attachment][attachment=45643]image.jpg[/attachment]

.webp)

Don't mess with the spring. There is no known calibration information available.

I'd be suspect of the spindle bearings, rollers, weight, shafts. They are set up to be as friction free as possible. What you show is typical. Replacement springs are obsolete. About all you can do if spring is a problem is swap for another used. As I recall there is always some tension on the spring and the tension increases as throttle is opened..webp)

Thank you for the pictures.

The spring IS adjustable via the collar it is attached to ( the collar is threaded onto the shaft and appears to be pinned) the spring itself is threaded onto the collar. So, in 1/2 turn increments, you can increase or decrease tension on the spring. I know this will not change the spring rate but perhaps the springs initial resistance to movement. On the other hand , if it effectively makes the spring shorter, it will be stiffer.

(When threading the spring onto the collar those spring coils are locked down and don't "spring" anymore.)

I ran the tractor for a bit afterwards and my perception is this was an improvement. I know - not scientific-

But easily reversed if need be. I can get some black smoke now and I could push a pile of dirt up hill.

( still under powered I think)

I understand a new spring is the answer and unavailable.

Changing the number of active coils = change in spring rate. That's how they are calibrated.

Increasing number of coils = spring rate decrease

Decrease number of coils = spring rate increase.

Agreed. Your explanation is much more succinct.