Have you pulled the key on the end of the shaft where the lift arm attaches and turned the gear 1/3 turn to get a new wear point on the gear? Or is all three areas of the gear worn out?

The big gear is very worn - all around - and the bottom worm gear has a broken tooth that is binding the big gear from rotating somtimes. Think it's time for a new set ...

The process is described in the #12 Servicemens Reference Book s/n 8T1-up. I'm out the door right now but will post the pages later today.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Gggsam.

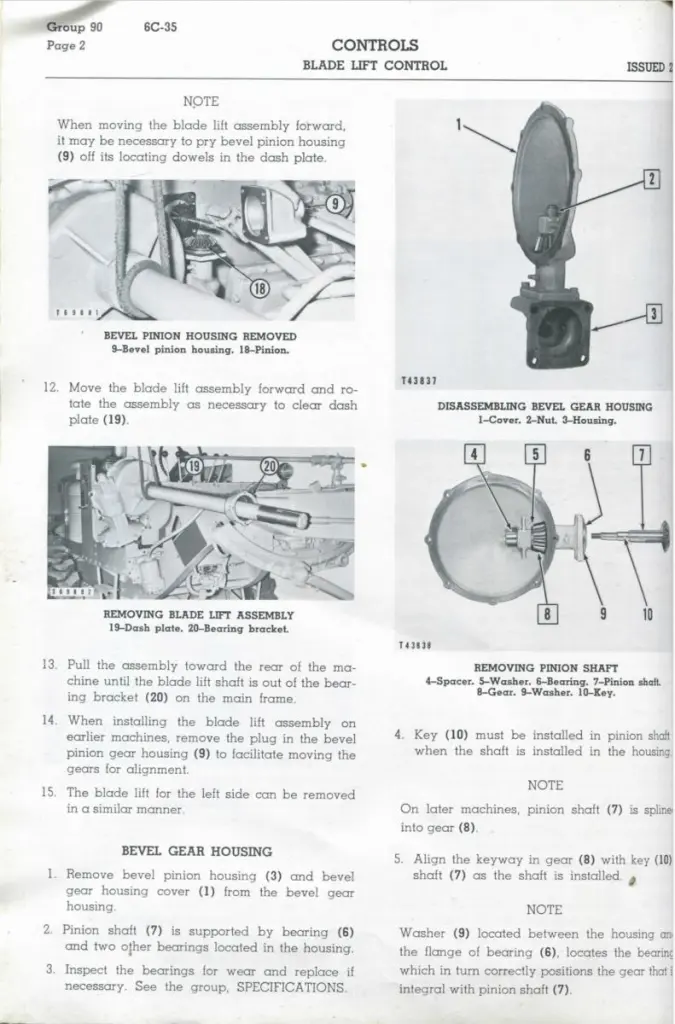

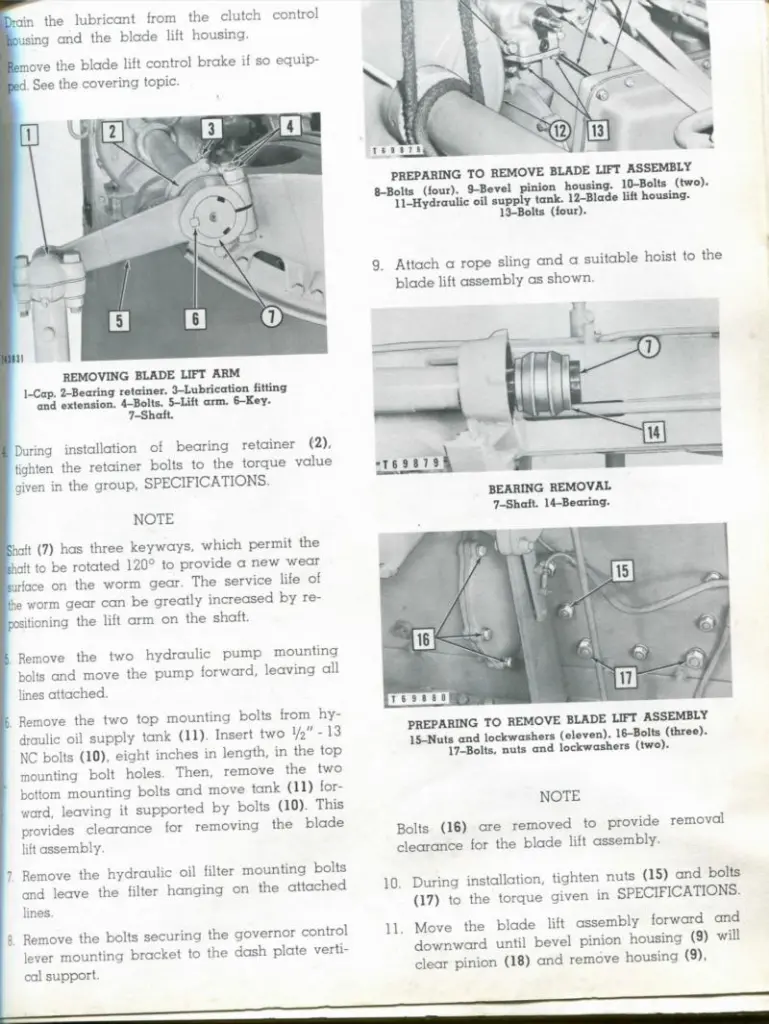

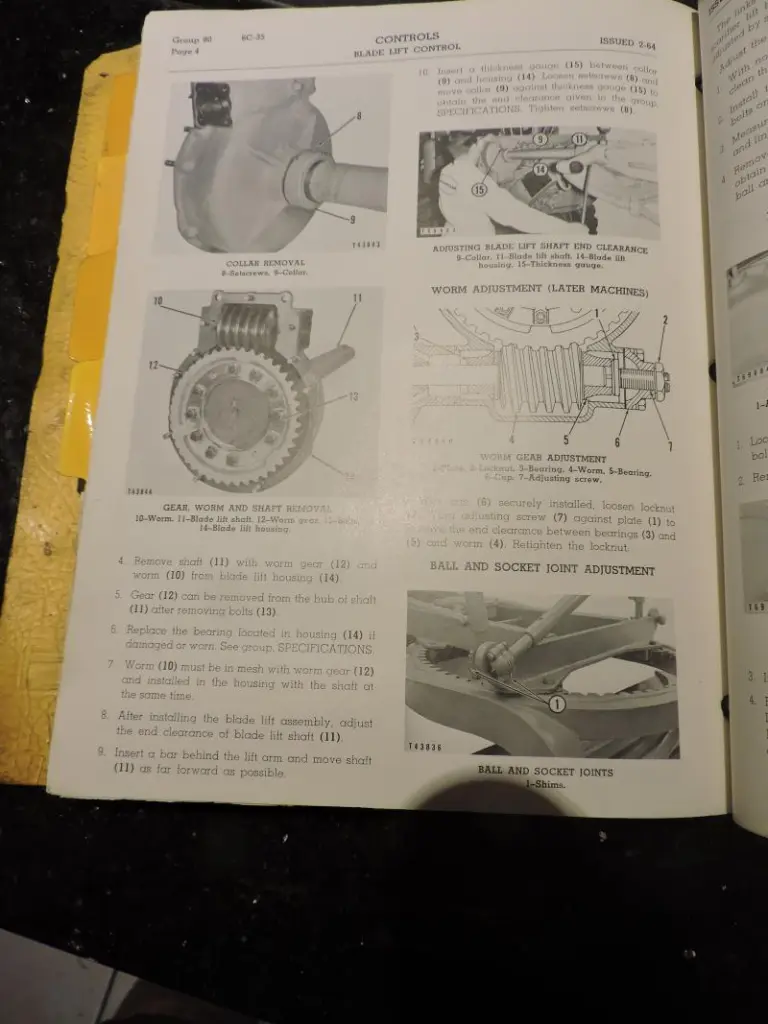

These scans are from the 99E-1 and up manual, but the basic procedure will be the same. Hope they help. I would start by draining the oils in the control box, bevel gear and worm drive housings first, as mentioned at the top of the second scan.

[attachment=45132]Blade Lift Removal_1_DP.jpg[/attachment][attachment=45133]Blade Lift Removal_1A_DP.jpg[/attachment][attachment=45134]Blade Lift Removal_1B_DP.jpg[/attachment]

BTW, you are lucky. This is the only manual that I have and I hafta return it at some point - just haven't seen the owner to return it yet.

Just my 0.02.

Offer to post still stands if you want an alternative version....

You have a wonderful day. Best wishes. Deas Plant.

Hi, Old Magnet.

How many views is too many? I'd say the more the merrier.

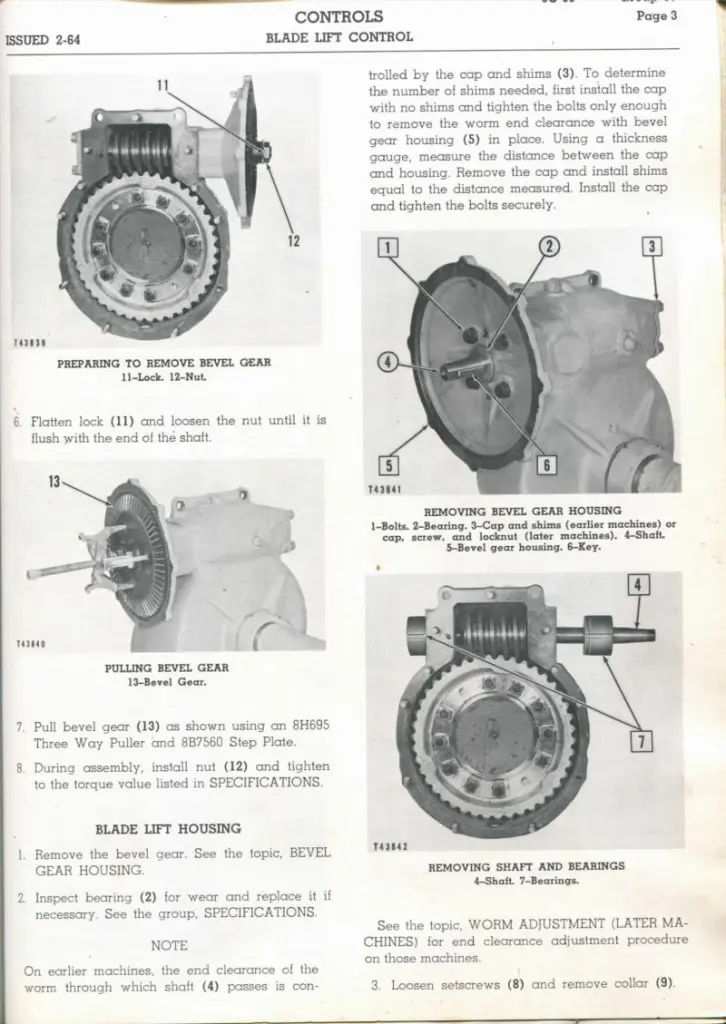

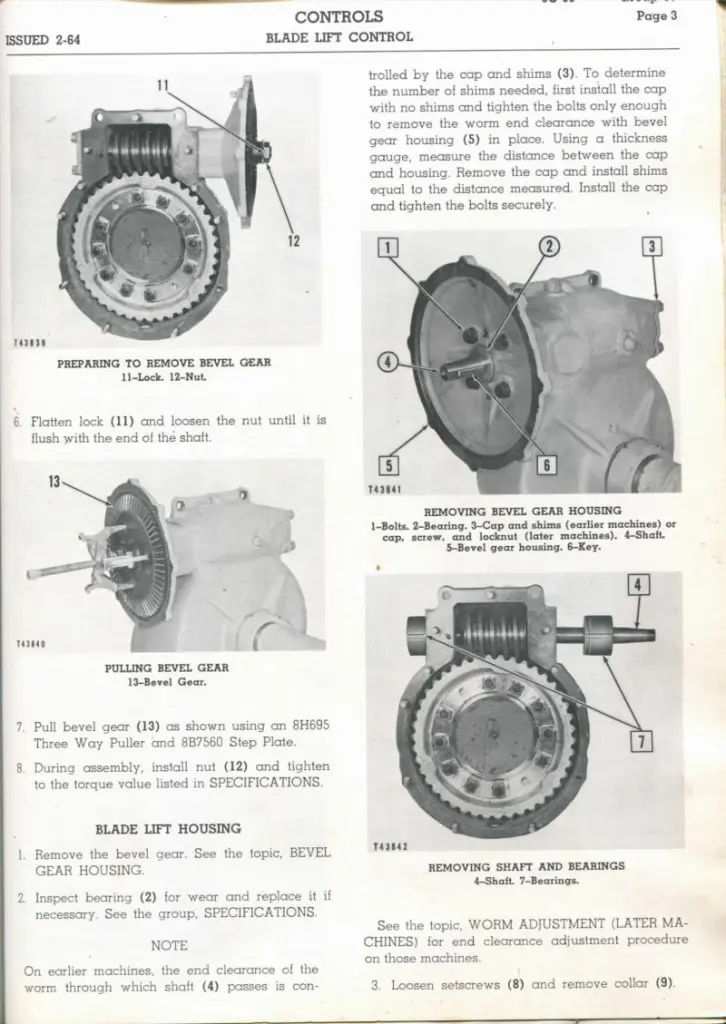

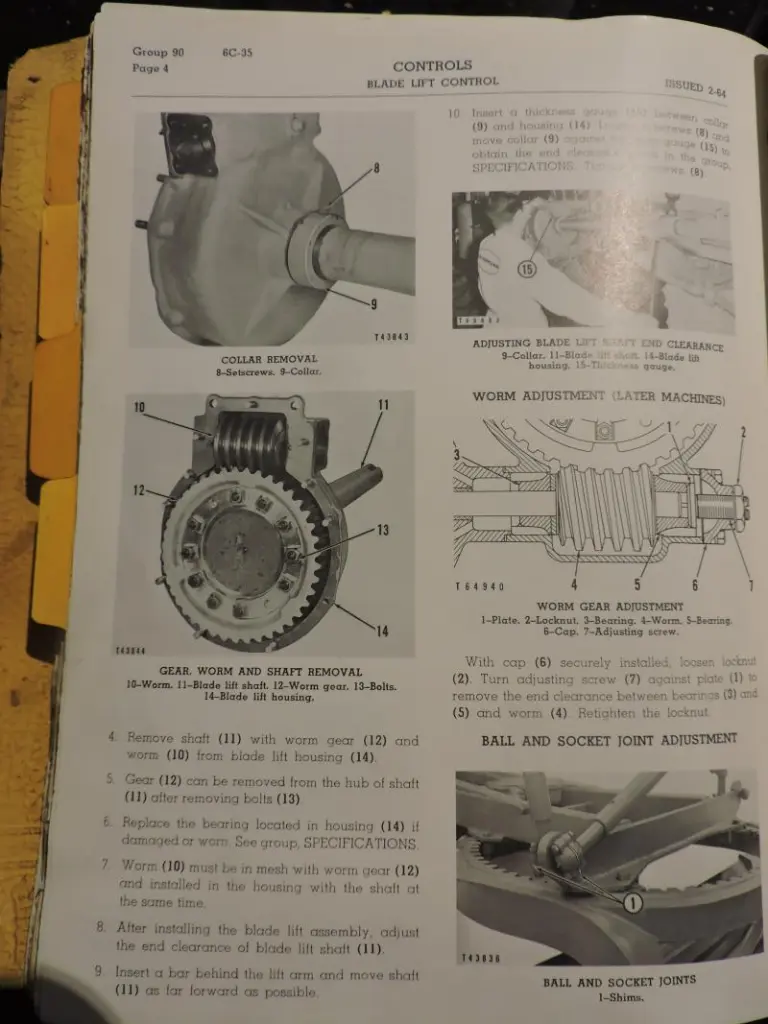

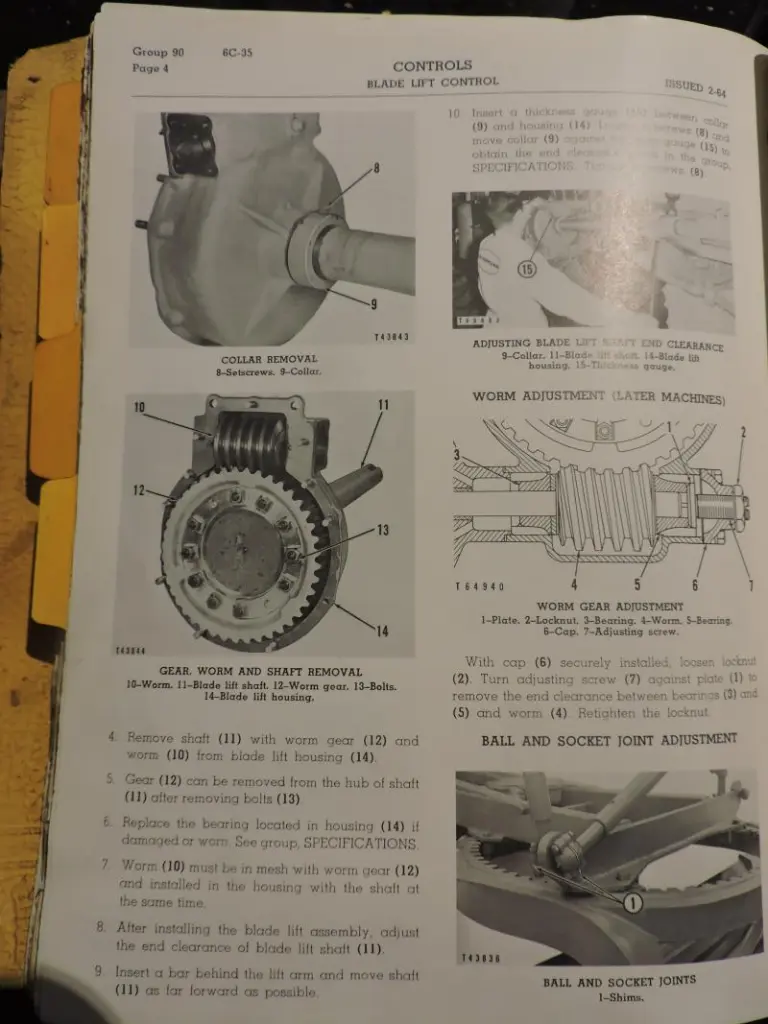

Here is the following page with the adjustments for re-assembly. Two views due to reflections on page when photographing. (Scanner temporarily offline.)

[attachment=45138]Blade Lift Gear Adjustments_1_DPscan.jpg[/attachment][attachment=45139]Blade lift Gear Adjustments_1A_DPscan.jpg[/attachment]

Just my 0.02.

The images are very helpful. Thank you.

Is the process as straightforward as it looks in the manual?

Anyone have any tips or tricks?

Again, thank you!

Sam

You have a wonderful day. Best wishes. Deas Plant.

Hi, Gggsam.

Is ANYTHING EVER as straightforward as it appears in the manual? I honestly don't know 'cos I have never had to take one apart. One company where I worked for a while did have to replace the gasket around the back of the high-lift gear case where it bolted to the front of the cab while I was working for them but I was out on a job on another machine at the time and didn't get to see it.

I would suggest following the manual 'religiously' and being patient. If you aren't terribly fussy about end appearances, it just might be helpful to use the oxy-acetylene 'enlarging tool' to increase the clearance slightly around where the large bevel gear intrudes into the cab. I don't think it will need it but it may. Sometimes it may not look like it but Cat design engineers are usually pretty good like that. And sometimes you just hafta know how to hold your mouth right.

Sorry I can't offer more information. Maybe you'll get to 'ed-jyew-mac-ate' us.

Just my 0.02.

Following up on this old post. I wanted to start the work last fall, but the Northern Minnesota weather had other plans. Just getting to it now.

In short, yes, the removal is easy as is looks in the book. The one kicker to remember is to loosen the bearing on the front of the lift shaft. If this is loose, there is enough play to swing the gear box out and work on it. At first, I didn't have this bearing loose enough. Much swearing was heard. After loosening the bearing and shaft, job was easy and my language improved.

New parts are on order. Will keep you updated on re-assembly adventures.

Thanks for the tips guys.

Much appreciated.

Sam

You have a wonderful day. Best wishes. Deas Plant.