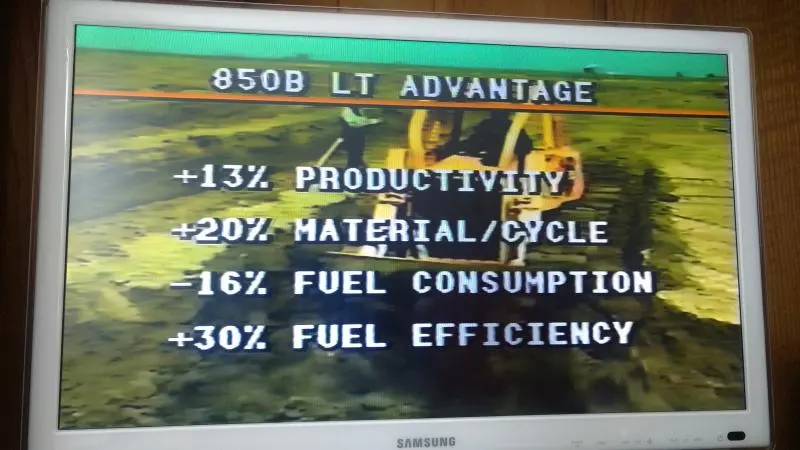

Lighter tractor, smaller engine, smaller blade but more productive? I wonder what the payoff was?

the 750b and 850b units are pretty scarce in my neck of the woods, the hydrostatic drive pumps and motors are vrtually obsolete as they were applied in those units, hard to get parts for 15 years ago, and financially restrictive, we had an 850 b coe to the shop that was mistracking, we pulled the pumps and drive motors, they were still functioning but completely worn out, the unit had 26000 hrs on it or so. price to restore drive units to factory specification was going to be about 40000 dollars, unit was woth about 15000 dollars. we advised customer, he didn't want it fixed, we reasembled it and put 15w40 oil in it. customer used it infrequently in a gravel pit for spreading reclaimed overburden and it worked fine for a few more years, lost track of it when moved away for a new job.

its been a lot of years but let me know if this sounds about rigth. the country where that unit was running we averaged about 3500 hrs on the lgp undercarriage, and about 7000 hrs on the narrower bulldozer undercarriage,

we used to cut the 30 inch grouser bars on the excavators down to 24 or even 20 inch grousers for one of the main city excavation companies, there units walked off a lowbed, dug a basement, walked on a lowbed, their units were seeing original undercarriage lasting upwards of 16 000 hrs, then they would bring them in for chains and sprockets and send them back out with the original rollers and idlers.

depending on the diligence of the operator, the excavators used to be able to go about 7000 hrs before complete undrcarriage replacement.

we used to put rock guards on all the hoes, and all the crawlers were completey rock guarded as well, which sometimes helped to mask undercarriage issues.

This doesn't mean a lot since U/C life is so variable in different underfoot conditions and applications, I was wondering how long the JD dozer U/C might have lasted in relation to a D6H doing the same amount of work.

You have a wonderful day. Best wishes. Deas Plant.

Hi, Folks,

I operated the FIRST JD 850 hydrostatic dozer into DowNunda at a demo field day in Sydney in, I think, 1981. It was a 'nippy' machine, plenty of power, handled well and very manouverable but, like a lot of small dozers at that time including a couple of Cat models, it was a little light on the front. I would have chosen a D6C or D over it.

My next encounter with an 850 was in 1996, for about 1/4 of an hour as part of a job interview - I didn't get the job 'cos their contract fell through and I still would have chosen a D6C or D.

I have operated several D6Hs and Rs and I would DEFINITELY choose one of them over an 850 - - -anytime.

We see VERY few JD dozers or track loaders around here. I suspect there may be a reason for that.

Just my 0.02.