Seems you have the spring number mixed up.

Original shim pack was 8 shims but I can't tell you how thick.

Shim away, your not going to hurt anything. No telling what had been previously installed.

Thankyou Pete, just what I needed, that parts diagram confirms I have the right spring 1H0332 (again thanks to you) though even with the "washer" and 8 shims the original spec is no where near 10% of the spring length I was thinking I could see in the Cat Hydraulic Systems book, I'll start adding extra shims and see what happens, luckily it's only about 20 minutes work to open up the pump.

Regards

Mike

If you are only making about 100psi, the problem is not the relief valve adjustment, I would be looking for a leak elsewhere and checking the pump vanes are fitted the right way round.

Hello Catsilver, thanks for chiming in, this #41 pump I have fitted to my D2 5U has been a major pain in the ring gear from the start and I've had 2 hydraulic pump experts work on it including the Owner of the local hydraulic shop and a semi retired Cat Mechanic, both who were confident it would work but I'm just not getting any pressure.

I found this pump at the back of a shed covered in dust and with the help of "Edb" we pulled it apart last year and Eddie found the broken pressure relief spring which gave me the wrong impression about it being a possible easy fix, the shaft bearings were worn out so I got the local hydraulic shop to replace those and the seal at which time he pointed out some nasty water damage in the cam ring, he said the pump "should" work but with that water damage he wasn't sure how long it would last, but through my own stupidity later on by fitting the pressure relief valve plunger in ass backwards the pump wouldn't develop any pressure, so I sent it over to a nice semi retired Cat Mechanic interstate who said he had a new cartridge kit for a #41 pump I could have, though when he got my pump in his hands he discovered his #41 cartridge kit was actually for a different pump and wouldn't fit mine, so we were back to square one, after hunting all over Oz he did find a new rotor and hand lapped the scored end plates and reassembled the pump saying it should work well but sadly it didn't develop any real pressure and when I took the pump apart after about 8 hours running found it was making metal filings, I had shown him my spool valve when I picked up the pump and he thought it all looked OK.

When I later pulled the new rotor out that had been fitted and compared it to the old worn rotor I discovered it did not have the 2 oil "galleries" machined at the base of the vane slots (see photo) so the vanes were hydraulic locking in their slots and cutting the cam ring and end plates so I got my Fitter and Turner neighbor Geoff to machine 2 oil 'galleries" in that new rotor and refitted it all after triple checking that the vanes were fitted with the rounded ends outward and that the cam ring was aligned correctly, incidentally there are all new rubber O rings in this pump. I had also measured the vanes carefully as a couple were tight in the new rotor(one vane was over one thou thicker than the others) so I hand lapped it so all the vanes were identical and slid easily in their slots, I'd also bought a new cam ring off Fleabay in Canada 2 weeks ago and fitted that so I was pretty confident I had all the obvious issues fixed now and so refitted the pump yesterday and found that while it will push oil even at low idle (previously it wouldn't, only at high idle), it still does not produce any real pressure so all I can think of is the pressure relief valve is allowing oil to be dumped before any real pressure is developed.

Needless to say this pump is driving me nuts, I've had it apart 6 times and 2 experts have worked on it and told me it should be OK but it is not, so I'm open to any ideas.

Thanks

Mike

Hello Catsilver, thanks for chiming in, this #41 pump I have fitted to my D2 5U has been a major pain in the ring gear from the start and I've had 2 hydraulic pump experts work on it including the Owner of the local hydraulic shop and a semi retired Cat Mechanic, both who were confident it would work but I'm just not getting any pressure.

I found this pump at the back of a shed covered in dust and with the help of "Edb" we pulled it apart last year and Eddie found the broken pressure relief spring which gave me the wrong impression about it being a possible easy fix, the shaft bearings were worn out so I got the local hydraulic shop to replace those and the seal at which time he pointed out some nasty water damage in the cam ring, he said the pump "should" work but with that water damage he wasn't sure how long it would last, but through my own stupidity later on by fitting the pressure relief valve plunger in ass backwards the pump wouldn't develop any pressure, so I sent it over to a nice semi retired Cat Mechanic interstate who said he had a new cartridge kit for a #41 pump I could have, though when he got my pump in his hands he discovered his #41 cartridge kit was actually for a different pump and wouldn't fit mine, so we were back to square one, after hunting all over Oz he did find a new rotor and hand lapped the scored end plates and reassembled the pump saying it should work well but sadly it didn't develop any real pressure and when I took the pump apart after about 8 hours running found it was making metal filings, I had shown him my spool valve when I picked up the pump and he thought it all looked OK.

When I later pulled the new rotor out that had been fitted and compared it to the old worn rotor I discovered it did not have the 2 oil "galleries" machined at the base of the vane slots (see photo) so the vanes were hydraulic locking in their slots and cutting the cam ring and end plates so I got my Fitter and Turner neighbor Geoff to machine 2 oil 'galleries" in that new rotor and refitted it all after triple checking that the vanes were fitted with the rounded ends outward and that the cam ring was aligned correctly, incidentally there are all new rubber O rings in this pump. I had also measured the vanes carefully as a couple were tight in the new rotor(one vane was over one thou thicker than the others) so I hand lapped it so all the vanes were identical and slid easily in their slots, I'd also bought a new cam ring off Fleabay in Canada 2 weeks ago and fitted that so I was pretty confident I had all the obvious issues fixed now and so refitted the pump yesterday and found that while it will push oil even at low idle (previously it wouldn't, only at high idle), it still does not produce any real pressure so all I can think of is the pressure relief valve is allowing oil to be dumped before any real pressure is developed.

Needless to say this pump is driving me nuts, I've had it apart 6 times and 2 experts have worked on it and told me it should be OK but it is not, so I'm open to any ideas.

Thanks

Mike

I guess you are trying to lift the blade to create pressure? Have you already proved that oil is not by-passing one of the ram pistons? You will not create pressure unless you have resistance to the flow. I'm guessing the relief valve pressure should be around 1750ps (its usually stamped on the valve) and even if you took out all the shims I would expect it to make a lot more than 100PSI. Is the pump noisy in operation?

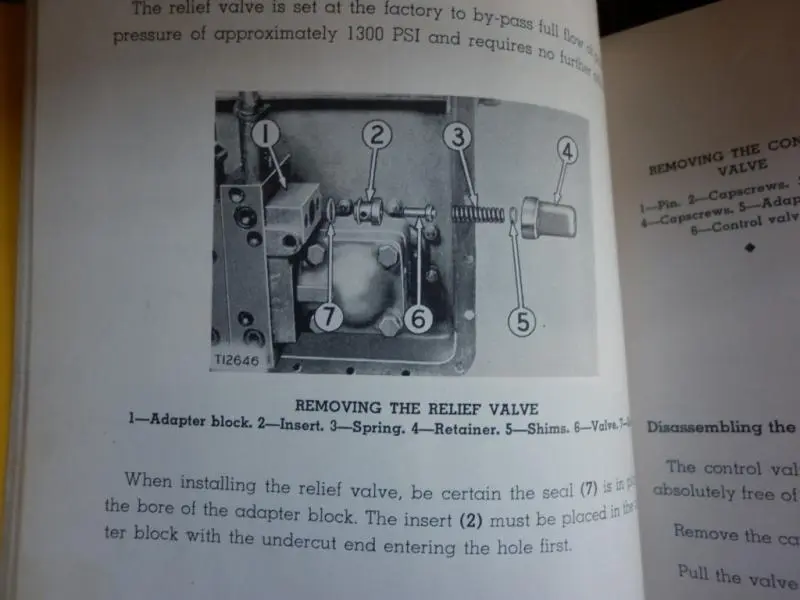

Thanks for your input, the pump is quiet and the oil in the tank will get warm over time, say half an hour, these #41 pumps only produce 11 gallons a minute at around 700 pounds with a peak pressure of 1100 pounds, I'm trying to run a double acting ram on a disc plow but this pump is pathetic compared to the old Vickers vane pump on my RD4 which I tested the other day at around 1200 pounds, what is interesting is the Cat Parts book picture from Old Magnet shows 8 shims and a washer under the relief spring that would measure just over 2mm thick I'm guessing yet the Cat hydraulic book photo shows a shim stack 2 or 3 times thicker in that #41 pump.

On my other hydraulic pumps you will hear the engine sound change as the relief valve opens, on this D2 I don't hear any change in engine sound when moving the control lever in any direction at either high or low idle with nothing hooked into the remotes at the back of the crawler.

Roger you are right, at least it is pumping oil now even at low idle, previously it would only move oil at high idle but without any pressure, I'll start adding shims, does anyone know roughly how thick the 4B4276 "washer" is?

Thanks for your help

Mike

Thanks for your input, the pump is quiet and the oil in the tank will get warm over time, say half an hour, these #41 pumps only produce 11 gallons a minute at around 700 pounds with a peak pressure of 1100 pounds, I'm trying to run a double acting ram on a disc plow but this pump is pathetic compared to the old Vickers vane pump on my RD4 which I tested the other day at around 1200 pounds, what is interesting is the Cat Parts book picture from Old Magnet shows 8 shims and a washer under the relief spring that would measure just over 2mm thick I'm guessing yet the Cat hydraulic book photo shows a shim stack 2 or 3 times thicker in that #41 pump.

On my other hydraulic pumps you will hear the engine sound change as the relief valve opens, on this D2 I don't hear any change in engine sound when moving the control lever in any direction at either high or low idle with nothing hooked into the remotes at the back of the crawler.

Roger you are right, at least it is pumping oil now even at low idle, previously it would only move oil at high idle but without any pressure, I'll start adding shims, does anyone know roughly how thick the 4B4276 "washer" is?

Thanks for your help

Mike