Engine is a D333, a 4.5" bore 6 cylinder that replaced the venerable D318 in 1959 or 1960 and was developed into the d330c with an increase in bore to 4.75" by the late 60's. The D333c was replaced by/renamed the 3306 in the 1970's

The fuel system is covered in a serviceman's reference book or tech manual for the D6b tractor. This is a change from the earlier tractors that had separate engine servicemans reference books and tractor SRB. Parts books have always covered all the engine and tractor parts in one book. The winch and dozer each have their own (smaller) books separate from the tractor books.

Ebay is a good place to find both original books as well as reprints. Your CAT dealer should be able to get you a high quality reprint of all books for your tractor.

The D6b was not too much different from the late U series D6 other than the D333 engine and the hydraulic pump and valve arrangement if equipped with one. Does yours have a towing winch or a cable control unit for the dozer or scrapers etc?

Have you attempted starting the engine with ether? Do you get white smoke while cranking or not? The rack is not so simple to check on that fuel system as it was on all the older engines. if you have good fuel pressure but no smoke while cranking it is pretty likely the rack is still in shutoff position for some reason. In any case where there is a possibility of a stuck rack, it's good to make preparations to smother a runaway engine by cutting off the air intake. Usually you can remove the precleaner cap from the air filter and have a piece of board to clap over the pipe. This is faster than disconnecting the fuel line if you have prepared in advance for this possibility.

Good luck!

If it's injecting fuel during cranking, it should smoke a cloud of white smoke thick enough to kill mosquitoes!

Just about have to change the fuel filter and clean the strainer in-line ahead of it (if it has one) before you go much deeper into it. While the strainer is open, check that fuel flows out by gravity in a good stream. Sometimes the tank valve or outlet spigot is clogged. To simplify priming the fuel system after filter change etc, a section of an inner tube with the stem in it can be clamped over the tank opening and inflated until it is tense.

While cranking, you should get low pressure flow of fuel out of any loosened injector lines even if the rack is stuck in fuel off. However, if the pump plungers are stuck up and not returning to follow the base circle of the injection pump camshaft, I am not sure you would get fuel out of injector lines.

The front end of the rack is accessible through a small cover on the front surface of the pump housing just below the accessory shaft housing that bolts to the front of the pump housing. This is used to check rack travel and set the rack position to install the individual pumps in the housing with special tooling. But you can remove the cover and put a punch or screwdriver in the hole and feel the end of the rack and push it toward the rear of the engine. It should push easily and probably return weakly from the springs and weights in the governor that is attached to the opposite end. If it doesn't move easily, probably time to remove the pump housing and send it to be repaired unless spraying in the hole with penetrant and working back and forth gets it loosened up.

Again, any question as to the proper function of rack and governor and its a good idea to prepare for a runaway. They're pretty exciting!

Hello, I thought it'd be funny to resurrect this old thread. After 4 years my Uncle and I were finally able to come together on a price.

I was able to get the engine running. The rack was stuck in off. Some lube and light tapping freed it up. I have a service manual, parts manual and operators manual now, but I'm looking to change the fluids and I have a few questions if anybody could offer up advice.

- The book calls for 7M3800 engine oil filters. Napa's website lists FIL1161. Does this sound alright using Napa Gold?

- I was planning on running rotella 15w-40 for the engine. Sound alright? It's what I run in all my diesel engines.

I'm a little confused on the rest of the tractor lube. The book calls for what seems to be engine oil in the flywheel clutch, steering clutch, transmission and final drives.

- For everything else but the final drives I was thinking of using universal tractor trans/hyd fluid 10w-30.

- The final drives seem like a 80w-90 gear oil would be ideal, but the book calls for sae 30, what do you all run?

Thanks for the advice.

Hello, I thought it'd be funny to resurrect this old thread. After 4 years my Uncle and I were finally able to come together on a price.

I was able to get the engine running. The rack was stuck in off. Some lube and light tapping freed it up. I have a service manual, parts manual and operators manual now, but I'm looking to change the fluids and I have a few questions if anybody could offer up advice.

- The book calls for 7M3800 engine oil filters. Napa's website lists FIL1161. Does this sound alright using Napa Gold?

- I was planning on running rotella 15w-40 for the engine. Sound alright? It's what I run in all my diesel engines.

I'm a little confused on the rest of the tractor lube. The book calls for what seems to be engine oil in the flywheel clutch, steering clutch, transmission and final drives.

- For everything else but the final drives I was thinking of using universal tractor trans/hyd fluid 10w-30.

- The final drives seem like a 80w-90 gear oil would be ideal, but the book calls for sae 30, what do you all run?

Thanks for the advice.

Thanks Ray. I have noticed the clutch will not release until the tractor has warmed up a bit. Even then it is still hard to stop.

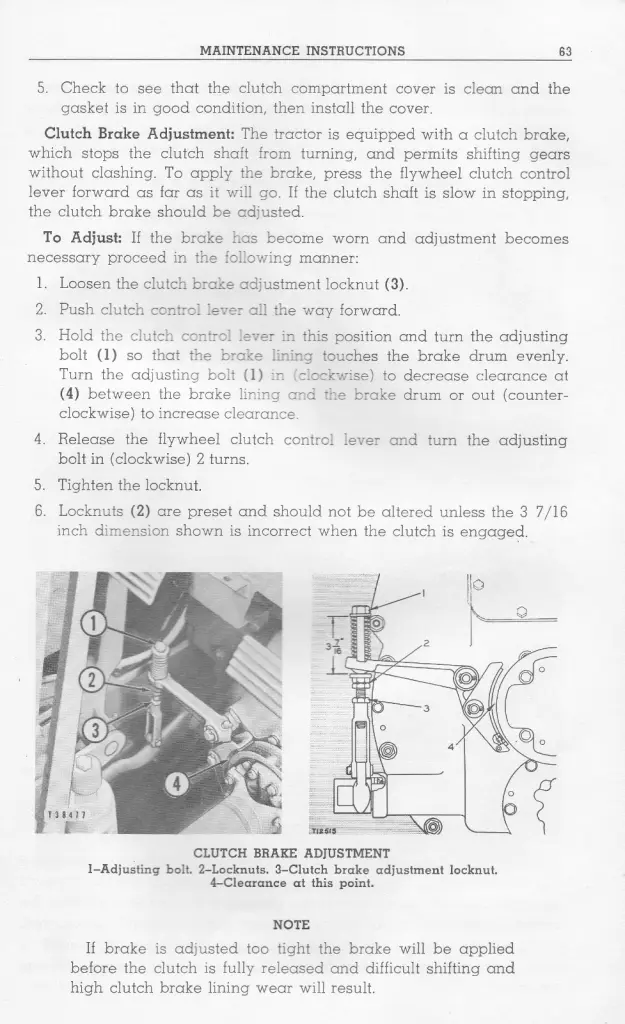

Hi Robert, I had master clutch problems on our D6B. We found that the linkage for the transmission interlock and the clutch brake were worn out. We made repairs and replaced the clutch brake and the clutch performed as new.

Craig

Started changing fluids. Engine has a touch of fresh anti-freeze in it, the green was setting on top the oil filters when I pulled them. Not sure how much it passes or where it passes. Maybe it's a easier fix like head gasket. The oil was a little milky. The block has always leaked externally a bit at jb welded crack in one of the cylinders.

Also was able to drain the flywheel housing and found a busted maybe bearing housing. Came right out the drain plug. I also managed to clean 8" of dirt off the bottom pan so that I could get the flywheel screen out and wash it off. It was pretty gunked up. Strange, though, there was like brass wires in the screen. Very hard to clean out. I had to pick them out.

Here's a pic of the metal ring I sorta pieced it back together. Flywheel housing seems to run fine.

[attachment=64361]c68ebcd87581b142ad812ff4c7edb795[/attachment]

"i reject your reality and substitute my own" - adam savage. i suspect my final words maybe "well shit, that didnt work"

instead of perfection some times we just have to accept practicality