If I remember right you take the power tower drive shaft out and slide the shaft forward as far as possible before removing the engine. I cant remember where we balanced at when replacing clutch.

Hi oldbeek,

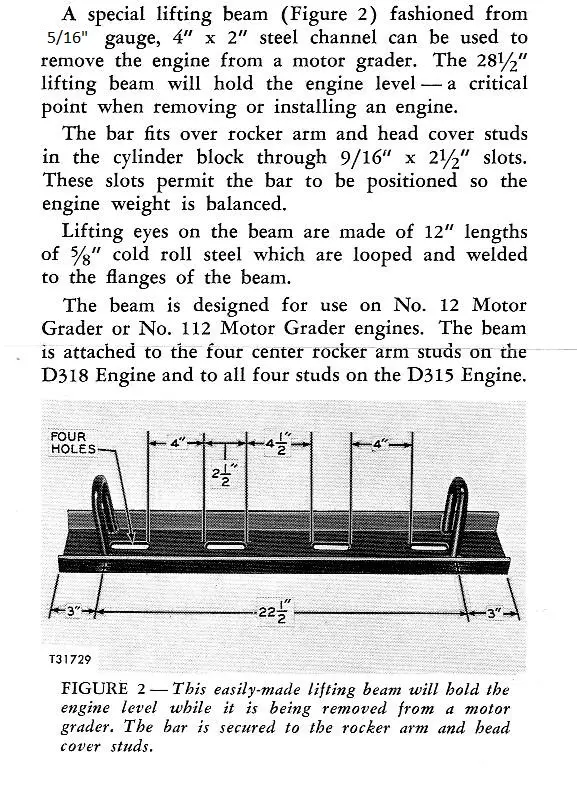

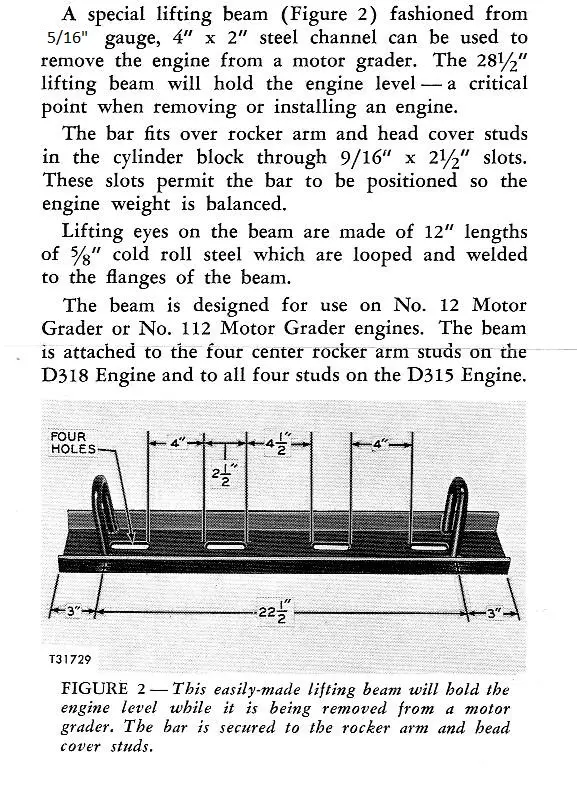

at the Dealer we used the fabricated tool in the scan below, it may help.

Cheers,

Eddie B.

If I remember right you take the power tower drive shaft out and slide the shaft forward as far as possible before removing the engine. I cant remember where we balanced at when replacing clutch.

Pete, do you think they might have any theories on the material to use if one wanted to run a bit of oil in a dry main or steering clutch?

when I did my oil clutch 12 grader the power take off shaft stayed put in trans. should be able to pull it out the flywheel by hand. if its trashed you can probably unbolt the clutch and slide it on to pto shaft to get your engine out. general gear in Idaho has new clutch discs for oil type. they were about $80 five or so years ago

Captain K