David Gruhot

D & G Excavating, Inc.

The last similar go round with same symptoms turned out to be a turbo packed with rust to where the engine couldn't breath. Ran fine with manifold removed as final check.

Hi Dieselholic92,

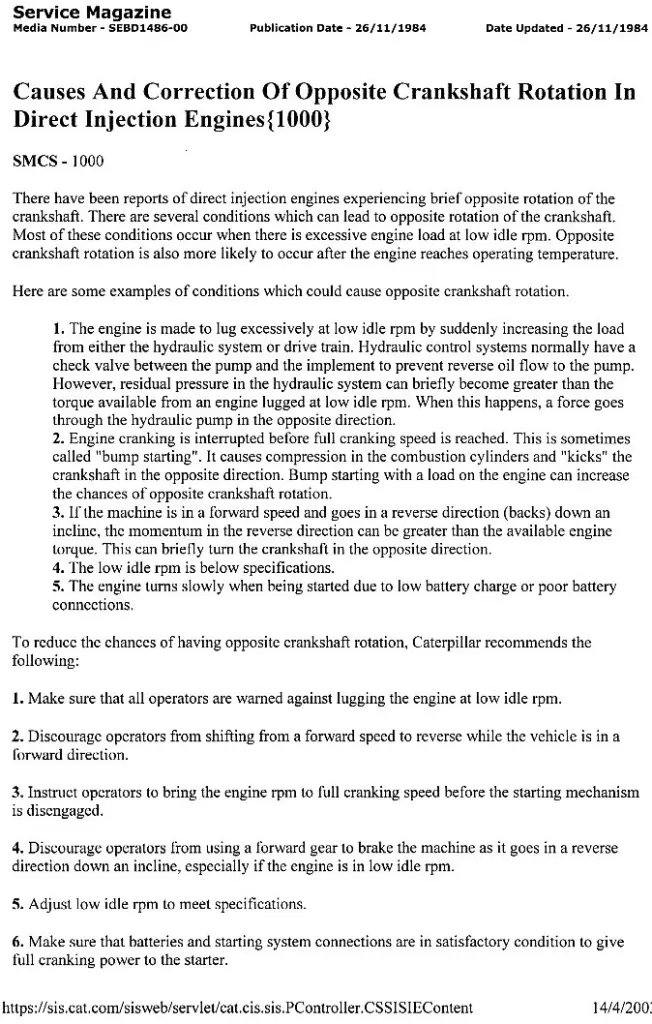

usual cause of soot inside the inner air cleaner element is that the machine was stalled on an incline in a direct drive and allowed to run backwards down the incline--the engine can start and run in reverse rotation direction ,BUT, you do not know it until the gears and hydraulics do not work--the soot does not come out the intake on dry air cleaner machines as the inner element does its job of catching the soot.

With old oil bath air cleaners you got oil soaked boots or worse.

Sometimes at low Idle if the hydraulics are stalled the engine can stall and the hydraulic system pressure can start the engine backwards too.

Have a Cat article scanned somewhere on the subject.

Even though the article is for DI engines it can happen with PC engines too--they may not necessarily have to start as they will make black smoke if driven/forced to turn backwards.

With the DI engines cat altered the injection pump cam lobe profile to stop this occurring.

Cheers,

Eddie B.

You didn't say which engine, tractor or scraper? Yours should be early enough to have 3306 in both.

I had a bad muffler that would blacken the filter through the dust ejector on a 621B but it had the 3406, and I see that yours is on the inside of the filter. Nearly has to be stalled and ran backward, probably on the front engine since it has all the parasitic load.

HI. edb hit the nail on the head.

Have seen it on CAT 3406 engines were they were run at low speed with heavy loads,

ie pumping engines etc.

Also observed in larger engines at a critical load and revolutions known as stalling

or barking turbos. Generally when exhaust manifold pressure is higher than inlet manifold

pressure at valve overlap, ie when exhaust valve is closing and inlet starts to open.

On one occasion the turbo compressor blades were bent backwards.

Had several large air compressors that were powered by 3306 DITA engines that were underpowered

for the size, (previously powered by D343's etc) and at times did not have the low speed grunt to

pick up the load as the supply volume changed. Fouled air cleaners and eventually high soot and

cam shaft failures.

Best regards

Would that be operator error and/or a lack of control systems to prevent the engine being overloaded that could allow those conditions L364? My understanding is that the designed peak torque rpm is the slowest an engine should run under full load conditions.

David Gruhot

D & G Excavating, Inc.

Thanks for the replies guys. This is an early 627B so it has a 3306PCTA in the front and a 3306 in the back. This is the rear engine I am talking about, I'm not positive if it is a DI or PC. I don't operate this scraper much, I spend more time in the other scraper. It could be possible that someone loaded it on the trailer or something with out the rear engine running, but I wouldn't know for sure. Would that cause this?

David Gruhot

D & G Excavating, Inc.

[attachment=34445]image.jpg[/attachment]

[attachment=34446]image.jpg[/attachment]

Hello

Yep your photo is a PC engine (can see pre-com chambers and glow plugs).

Interesting that it is the rear engine as from what I can remember it drives

through a 4 speed torque convecter drive transmission, were as the front

engine drives via an 8 speed transmission where the top 6 speeds are direct

drive and also the front engine drives steering and implement hydraulic pumps

which will load up the engine especially open to poor operator practices.

BUT I stand to be corrected.

Best regards

David Gruhot

D & G Excavating, Inc.