Reply to Old Magnet:

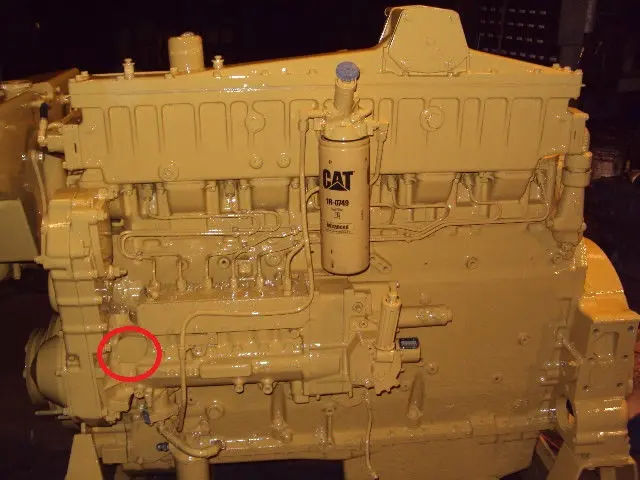

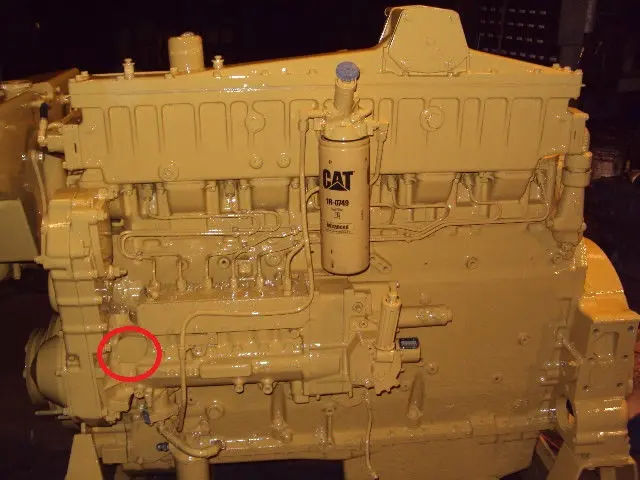

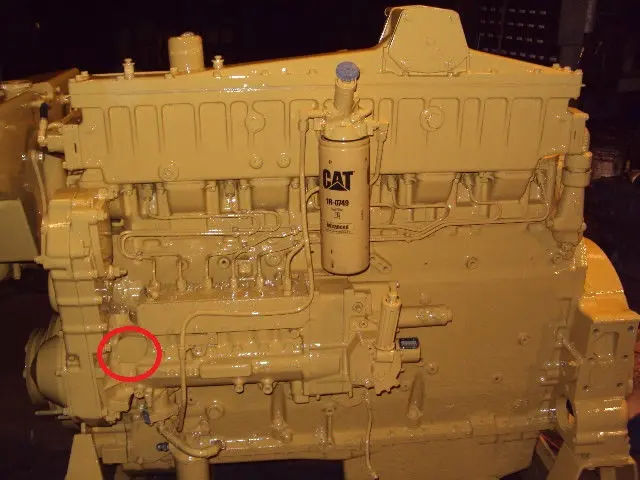

Don't know anything about Cat truck engines but here is about the best picture I could find.

Hi Eric,

the 3406B injection pump is the same scroll (Bosch) type setup as any Cat pump. This is NOT a Sleeve Metering style pump--can be confused as such due to the plate on the side.

The plate on the side is the fuel gallery that the injection pumps draw from and indeed pump back into when the rack is in the stop position.

Rack is likely stuck or a pump and its lifter is stuck up. If a lifter is stuck up the pumps bottom plate will need to be removed to see if you can get to the lifters to pull them down --this action should release the pump plungers/rack

As suggested remove the stop solenoid and see if it is stuck in the shutoff position.

Also remove the Air Fuel Ratio Valve and see if the linkage it connects thru is stuck.

Thru the oval 2 bolt cover at the front (left in the scan) side of the pump body (circled in red on OM's pic scanned below--Thanks OM) you should be able to get to one end of the fuel rack and see if you can gently move the rack and also see if any moisture has been in there.

There can be a separate manual shut off shaft out the side of the Governor housing that could be stuck too, or allow you to gently move the rack.

The fuel coming from the pump bonnets is slow because the delivery valves in these direct injection pumps is a dual valve affair that has a secondary return valve in it to allow return pressure spikes to return to the pump side of the valve, both sections of the valve have a very strong spring in each section--not weak one like the old pre-chamber pumps have.

The main part of the delivery valve has a groove machined in its sealing face to allow leakage back also and the fuel you are seeing comes thru that groove--the delivery valves are not a positive seal like say a Bosch type delivery valve.

The fuel return orifice/valve allows about 9 gals an hour to return to the tank to keep the pump cooled and bled of any air that may build up in the supply gallery and hinder injection.

Hope this helps.

Cheers,

Eddie B.