Reply to Rep0144:

Thanks for the parts break down this will help big time.

I want to get this dozer back running right, my dad used to run this dozer right after it was bought new, (deep plowing to get some top soil back to the top), right after the 1951 flood west of Topeka Ks.

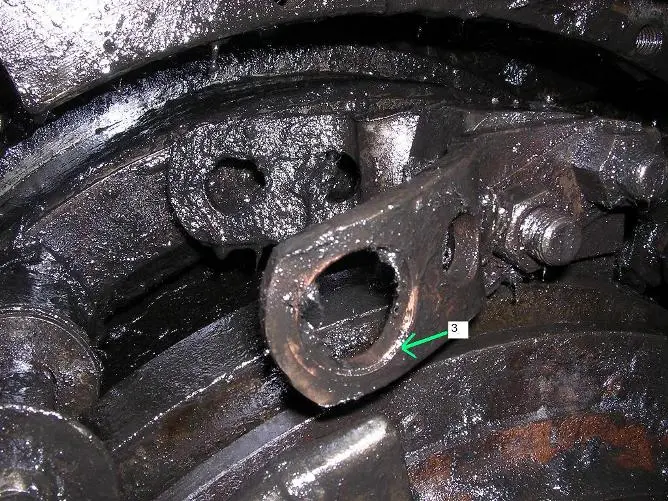

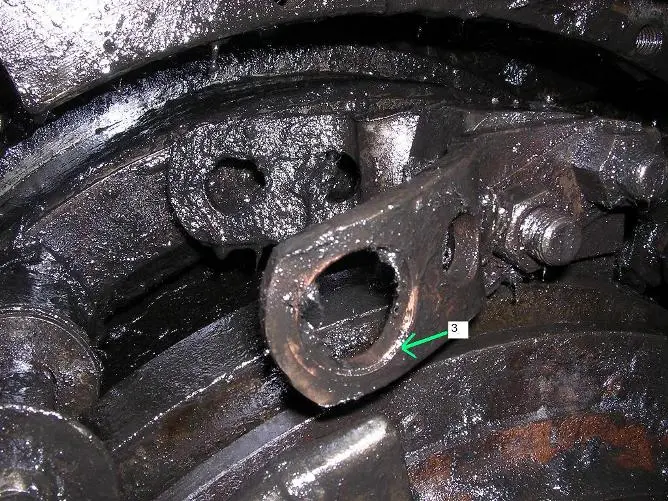

Where did the oil come from, looks like all the parts are coated, friction material looks dry though.

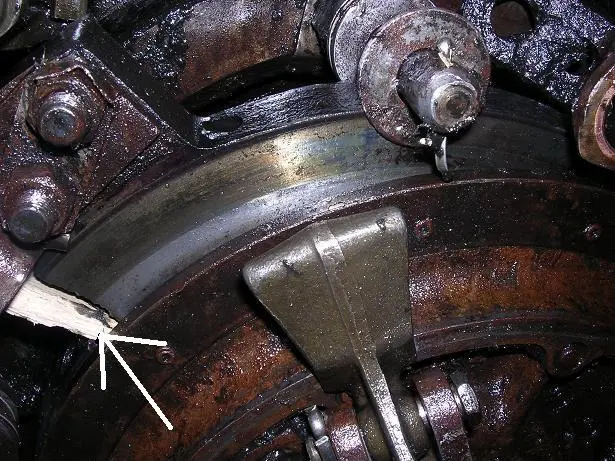

Talk about a mess, I have a D7 that apparently never saw any grease in the pilot bearing long before I got it, 15 hours later on the meter, the drive links that connect the main flywheel and clutch assembly could not take the strain anymore, the thick driven plate in between the 2 clutch plates was wobbling around when the clutch was not engaged and I assume when the clutch was engaged it grabbed the plate wherever it landed, lot of vibration, fenders were flapping, I knew something was up, and then the smoke started coming out of that compartment, the links let loose and the material left in there was like a big mouse nest, the links rubbed off on the upper bellhousing, so I shut it down, eventually removed the clutch assembly, and found that the pilot bearing was disintegrated, the bore eggshaped. Mind you, I realize the later oil clutch is far more durable, but the fact that this thing held on for as long as it did is amazing, if you keep an eye on things, and knew it needed some work, you certainly had enough time to get the tractor out of the field etc.

This clutch original, the tractor was owned by the corps of engineers until 1970, so I can see what happened, they kept the O.D. green paint up to date on it, probably ran it every so often, but was never used, until bought by a farmer, I think I'm the 3rd owner. There is a metal data plate rivetted to the inspection cover, that says, grease daily, (pilot bearing) ironically, that never occurred, LOL !

I was a bit intimidated or a little confused about what to do with this assembly, luckily I found a good used complete clutch assembly from a dismantler, from a running tractor. The friction linings were useable, but I decided I won't reinstall the clutch until the linings are replaced, both clutch brake and clutch plates. I was aware that the friction material, (segments) are available, but wondered if the holes were drilled in them, that would be a pain in the arse to drill them from a template of the old segments, then counterbore the holes for the rivets, then do all the rivets and attach the segments, you can get the hand tools from Cat, it's in the tools and supplies catalog, the old catalog from the 50's even shows the rivet press.

It did not make much sense to do this work, when you should probably be able to utilize an outfit that manufactures/installs friction materials, I had found a couple of places that does this work, over 100-150 miles away, nothing local yet although I've yet to call some of the crane outfits to see if they have anyone local that does friction work, should be a done deal then.

The only issue I had was about the thickness of the friction segments, wondered if anyone knew how thick they are, and what type of friction material is best, the outfits that do this work would probably be able to recommend the correct material, but how do they know how thick the material is supposed to be on one of these when it was new?

In the interim I've been turning the motors over by hand monthly to make sure they don't seize up, been sidetracked on other projects sitting in the yard, but I think I'll get to finally get the clutch done before winter.