If it's convenient, clamp the barb onto a cylinder etc and then you can more easily wiggle and push the hose so it basically crawls onto the barb.

Barbs are all in position on tractor and cylinder. I guess it's just brute force, eh?

Try putting the hose end in boiling water for a few minutes, dry it and spray WD40 in it.

Lube, lots of lube. Then brute force.

hydraulic is is not slippery or at least thats what I have always been told so, I was told to use engine oil for fitting off hydraulic hoses works much eaiser than hydraulic oil

Paul

OK. Thanks all. Tomorrow will try some heat and some motor oil.

I took a block of wood and drilled a hole slightly smaller than the hose diameter then cut it in half.

Put rosin on it then I could clamp the hose in a vise. Used dish soap for lube and a plastic dead blow hammer. to help pound the fitting in. worked pretty well

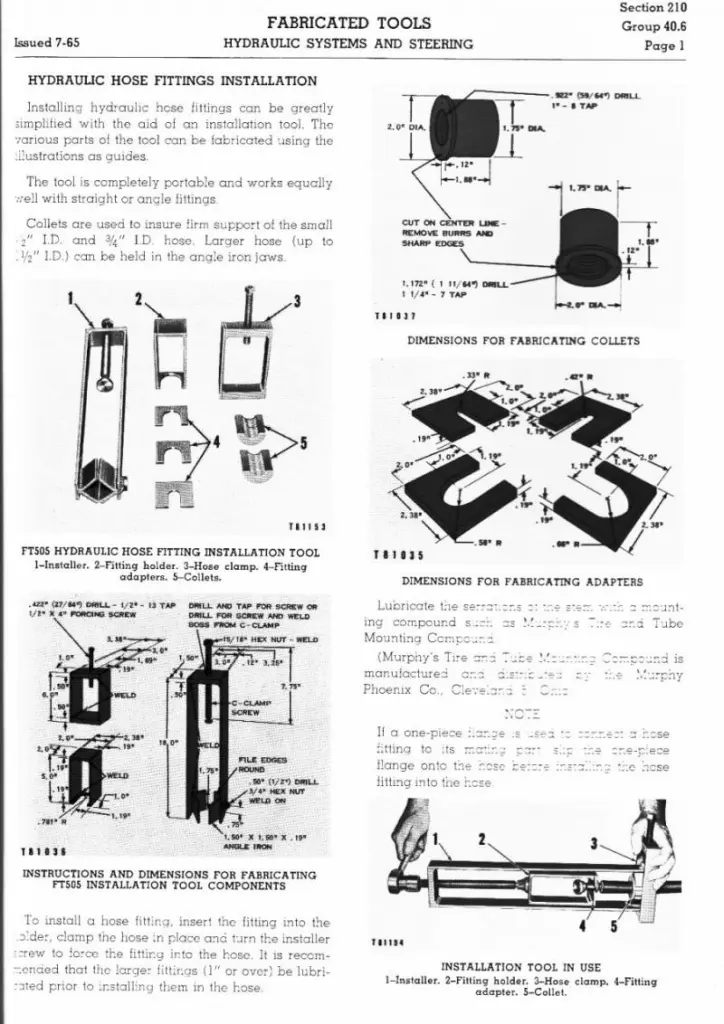

The directions from edb said to use tire compound like Murphys. I have used grease and a large mallet.