Reply to Old Magnet:

Need to run some pressure tests on the system to see whats going on.

To start with get a pressure check on the transmission pump. Should be a tap on the oil filter. Should make 343-367 psi with engine at high idle and selector lever in neutral.

Hi DP,

before you carry out OM's suggested tests above it is wise to check the Transmission Filter Element for metal or other tell tale signs of a problem.

Also check the transmission pump suction screen for clogging from brake linings, etc. breaking up.

This will cause low oil flow thru the system and inhibit cooling capability.

If all is OK then carry out the trans pressure tests, if they are OK then carry out the cooling system tests as per the scan below. You are looking for the temperature differences across the coolers and the radiator top and bottom tanks--ie water temperature into the rad as compared to the temperature of the water out.

Temp drop across the oil cooler should be 15deg F to 40deg F in normal operation. Leaking clutches or other components in the transmission hydraulic system will cause low oil flow thru the trans oil cooler--the evidence at the cooler will be a high temperature differential as measured at the trans/torque converter oil cooler oil inlet tube and outlet tube.

If Overheating then check for blocked cooler, high coolant temperature (from lower radiator outlet) or low oil flow caused by leaks in thee trans and t/c oil system.

It is not unknown for a poorly maintained cooling system to shed rust etc. and cause a blockage to the water flow into and thru the trans and engine oil coolers-- From memory these units have water cooled trans oil coolers.

The engine may not also show signs of overheating even though the trans can overheat--once saw a new machine trans dismantled because of trans overheating, but the engine did not when they were tested, it was found that due to a faulty water pump impeller--low water flow caused a similar symptom to the oil cooler tube blockage mentioned above.

Oil usually flows thru the trans and then the engine oil coolers before cooling the engine cylinders/head etc.

Ensure that the radiator fins are not blocked with grass, mud, oil and dust build up there by restricting air flow thru the core.--same goes for air type trans oil coolers as fitted to earlier 955's.

This can be done by checking with a torch or shop lead light held one side of the core and viewing the light thru the core from the opposite side.

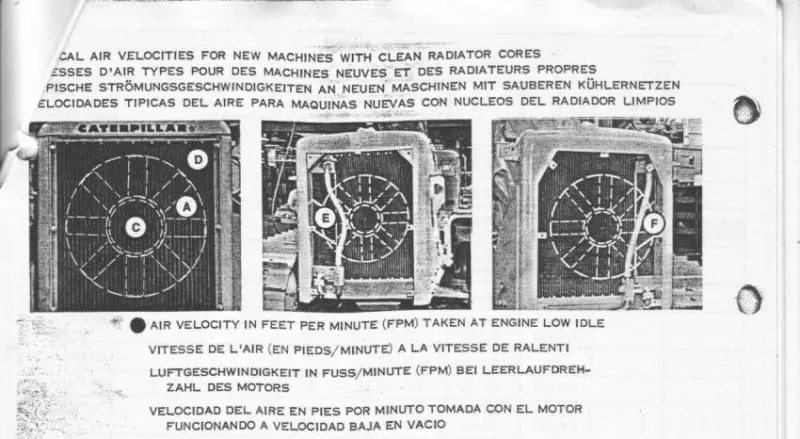

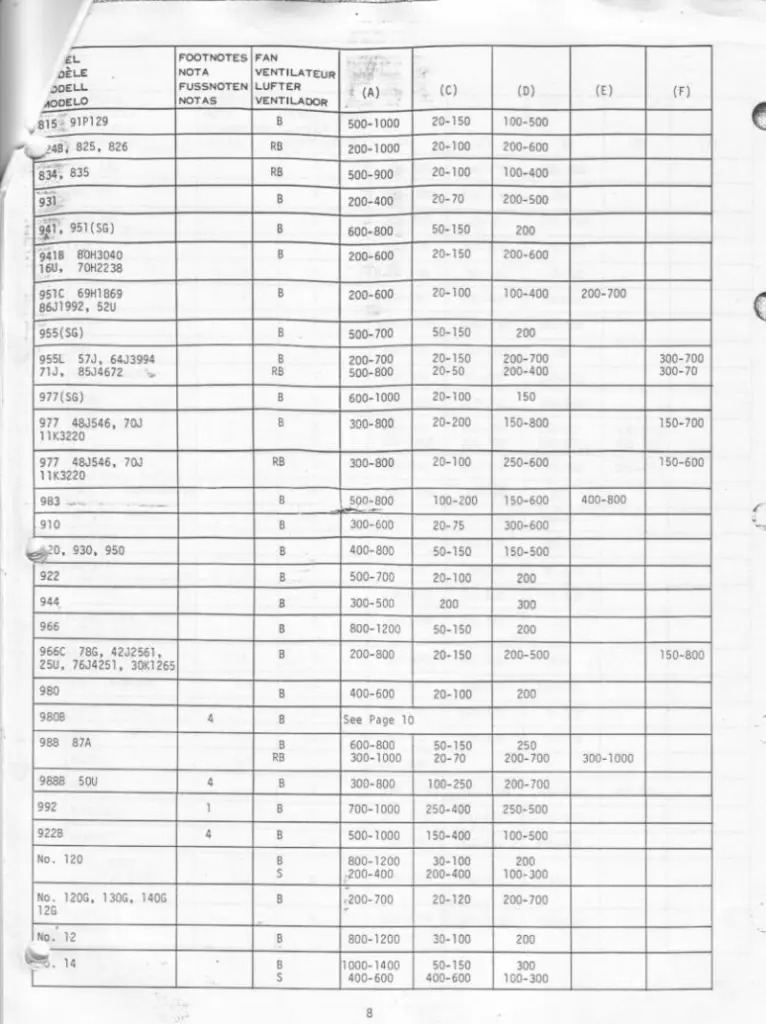

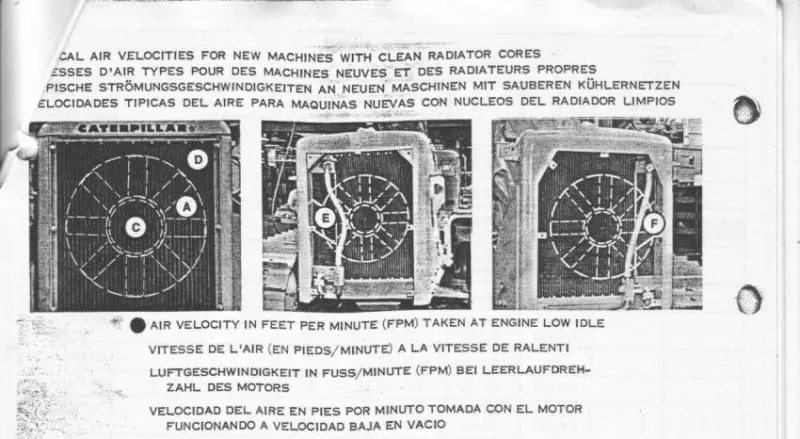

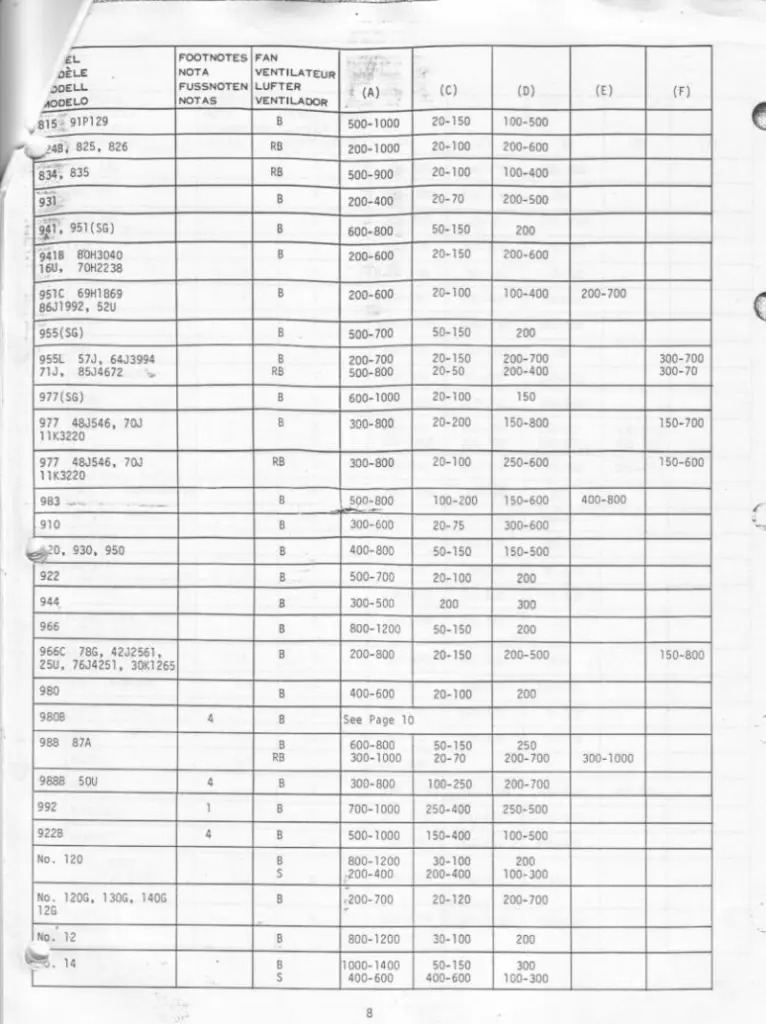

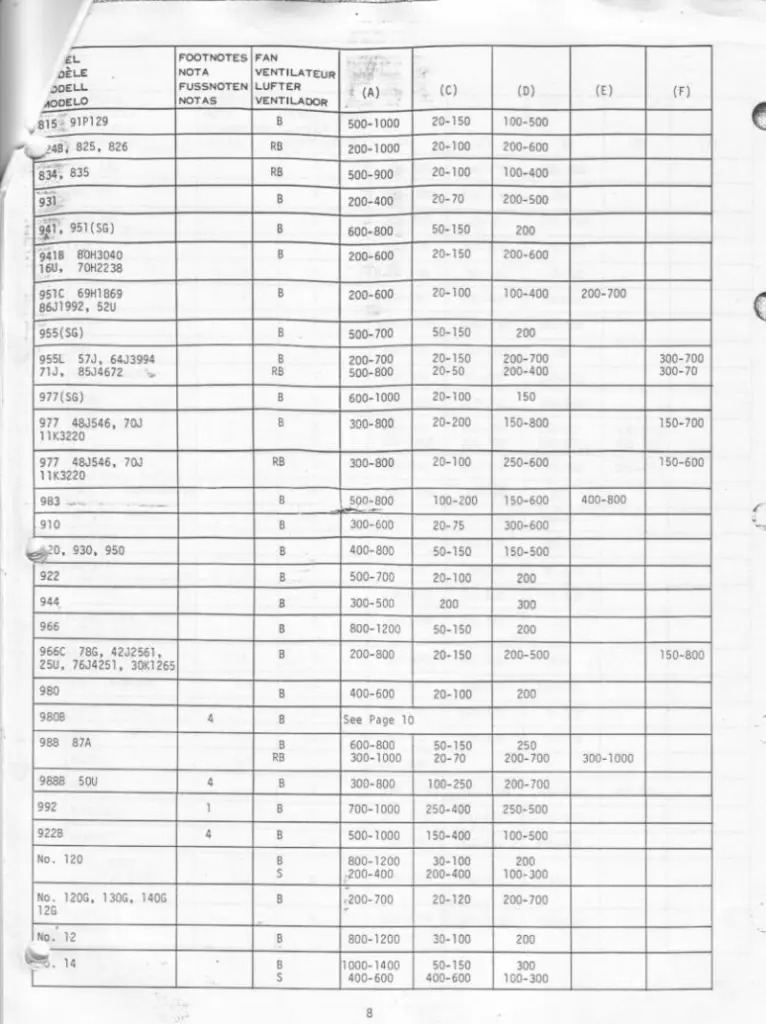

The other scans below show air flow checking positions--check all over the indicated areas with an air flow meter and compare the results with the scale Caterpillar has given for your 955L--these flows are for unblocked clean cores.

The "B" and "RB" in the Fan box is for Blower and Reversible Blower fans.

For reversible fans it is not unknown for the blade retention plates and the hub to wear and allow the blades to effectively flatten out some and not pump full air flow.

These reversible units are usually only intended to be used to clear the cores of trash by reversing the flow temporarily.

Hope this helps.

Cheers,

Eddie B.