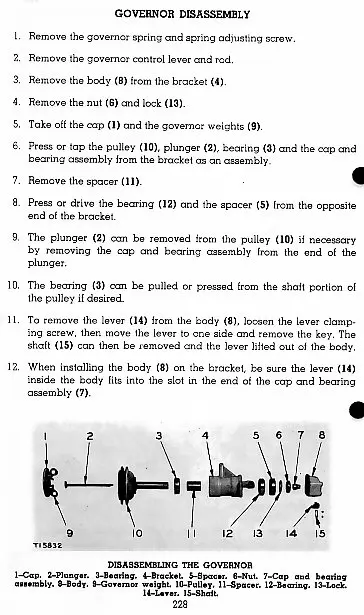

Yes It should have a little bit of oil in there, but everyone I have pulled apart never has. I put a little ATF oil in the pulley end and a little ATF oil in the linkage end as well. To get that nut off you will need to remove the slotted part in your picture. I made an attachment to pop it off with a slide hammer puller. It has a bearing inside that is a tight fit on the shaft. Once that is off you will be able to slide the rod out.

Once that nut is removed the shaft will drive out of the housing so you can replace the bearings. Last set of bearings I bought through Florin tractor parts were cheap as. If the bearings are rumbly/sloppy just replace them and be done with it.

Hi Jessie,

like Billy wrote, that piece contains a small bearing that is a press-fit on the rod, so just pull it off - I think I removed my two with a couple of screwdrivers and some blocks of wood.

Billy, did you replace that bearing in the slotted piece? Just curious - I didn't as it spun smoothly but I did replace the other two.

[quote="Neil"]Hi Jessie,

like Billy wrote, that piece contains a small bearing that is a press-fit on the rod, so just pull it off - I think I removed my two with a couple of screwdrivers and some blocks of wood.

Billy, did you replace that bearing in the slotted piece? Just curious - I didn't as it spun smoothly but I did replace the other two.[/quote]

Gday Neil.

Yes I have replaced that bearing in the slotted piece before. I had one that had rusted tight. The old bearing was tricky to remove so I bought a new slotted piece and a new bearing from Florin tractor parts.

Cheers

Billy

Thanks guys that is very helpful ! would you know the part #'s for those bearings The tractor is a 5u4149

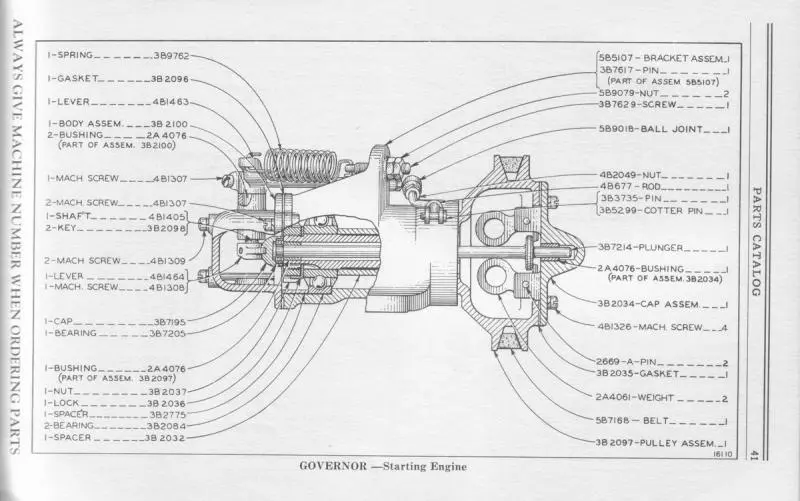

The 2 big bearings are both a 3b2084. The little bearing in the slotted cap is 3b7205. The slotted cap is 3b7195.

Hi Team,

horizontal pony gov. data in one place.

As described in the last scan below.

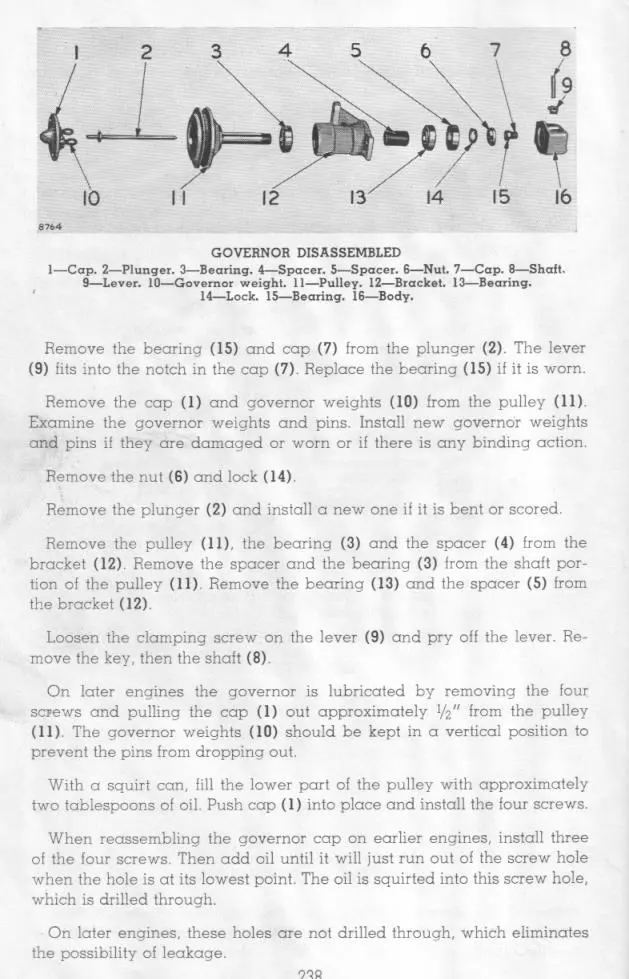

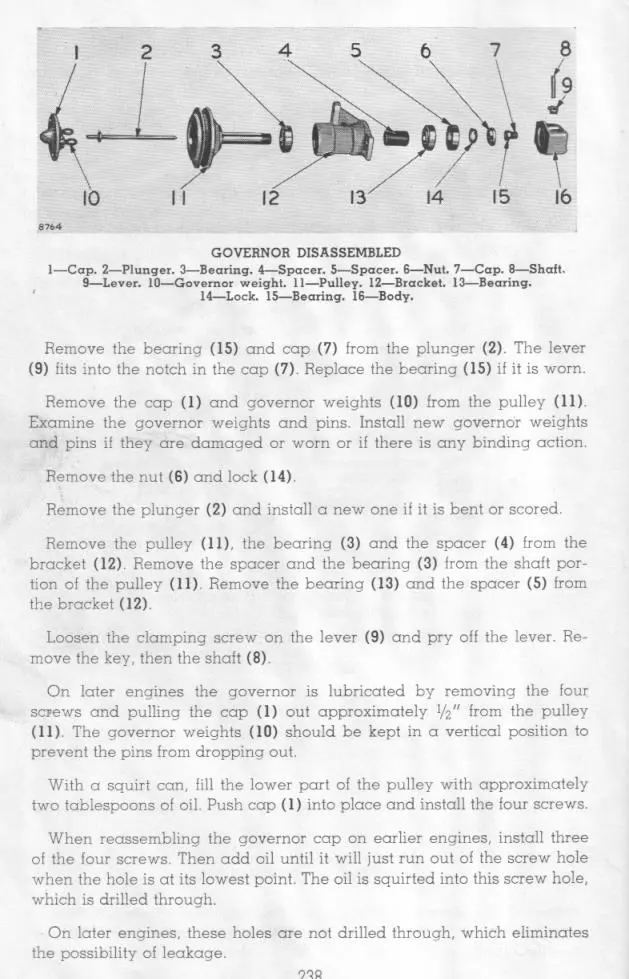

The best way to lube the early governor is in its working position (horizontal) for Early D6 "R", D4 "G,J & T" D2"J" and possibly some early D2,D4, & D6 "U" Series machines.

If it has thru drilled cover plate screws is to rotate the pulley until 2 of the 4 screws in the front cover plate align vertically, remove upper and lower screws and one other screw for air to escape, inject oil with a pump action oil can into the upper screw hole until oil flows from lower hole--replace screws.

Doing the lube as described in the second of the scans below is for later D6 "U", D4 "U", D2 "U" machines with NON thru drilled cover plate screws is by pulling the front cover out no more than 1/2" as described in the scan below, further than 1/2" can allow the governor weight pivot pins to drop out and be lost.

This data from relevant SRB's.

Correct High Idle Speed for D2, D4 & D6 pony engines is 3350 RPM.

Cheers,

Eddie B.

NOTE,

the above data comes from D3400, D4400, D4600, D311, D315,D318, SRB's.

Regardless of these facts, Common Sense should prevail, as parts do get swapped between early and late engines and this data then is no longer valid as to exactness.

Using Common Sense --if it has thru drilled cover screw holes--well and good, expect it to leak oil past the screws.

If it has blind holes , pull the cover plate out the 1/2" and oil away.

I think a lot of discontent about whose gov. has what is due to parts swapped in the life of the unit.

I stand to be corrected but, I think this is close enough--no need to flame anyone because their swapped parts unit does not fit the data I have spent time researching.

Keep smiling, at the end of the day it does not change how the thing works.

Quick question , I had my governor off and in a vise , I gave it a few spins by hand and it seems to bee off balance ,the same spot on the pulley always ends up at the 6 o'clock position , is this normal?

I seem to remember describing that oiling procedure only to learn that some (probably early) had blind screw holes.

The 2 big bearings are both a 3b2084. The little bearing in the slotted cap is 3b7205. The slotted cap is 3b7195.