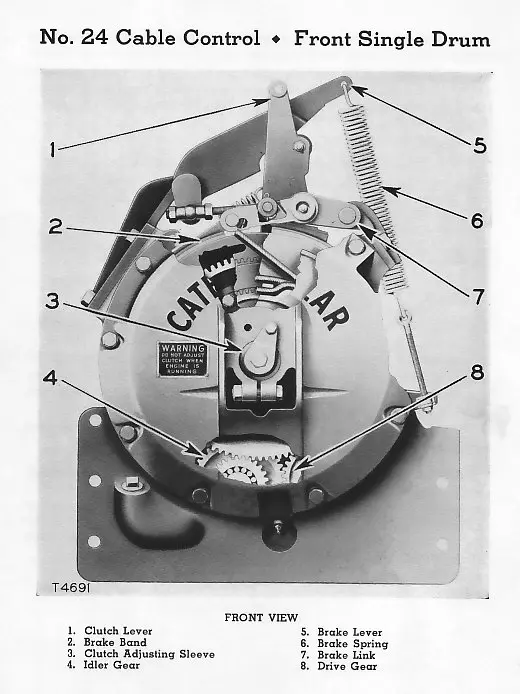

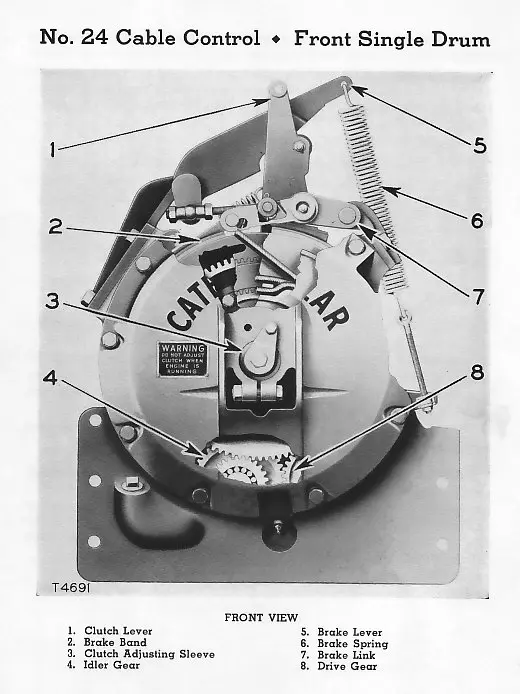

It's a #24 unit but that front cover with high guards on the side of the shaft clamp indicates it is a model 33E1-up. Still correct for the 3T but a later version than the usual 8D501-up units. To complicate things more the 4F4943 cover interchanges with both and there are three types of 8D501 models.

Still odd in that it doesn't have the shaft lock feature that is used on most but not all units.

I'm thinking it is a 33E1-up unit.

Hi Team,

was not unusual to weld on a bigger nut to facilitate clutch adjustment as the normal 3/4" head--if IRC-- as standard usually rounded off with abuse, or rounded off by lock plate if late enough unit to have it fitted or had been modified to be fitted as it was found that the sleeve would back off the clutch adjustment.

This usually occured as the clamp bolt threads stretched and the nut bound up on the clamp bolt threads so the diminished clamp force allowed the sleeve to back off.

Yep, must be earlier unit with only the clamp bolt for holding the clutch adjuster sleeve. Often did not hold sleeve effectively so the lock plate was fitted later--see scan below for pic of lock plate--easy to make one and drill and tap threads to suit--if I recall were 3/8" UNC.

Cheers,

Eddie B.

Take a look at norcalisdank's 4R D6 with ccu. Looks to be the same unit in which case I'd change my guess to an early version 8D501-up. Maybe he can supply a s/n for the ccu he has.

Hi John,

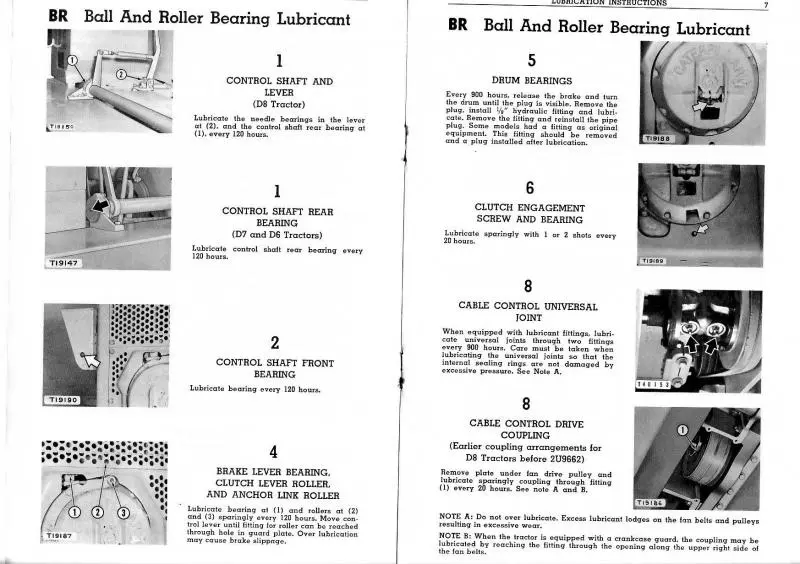

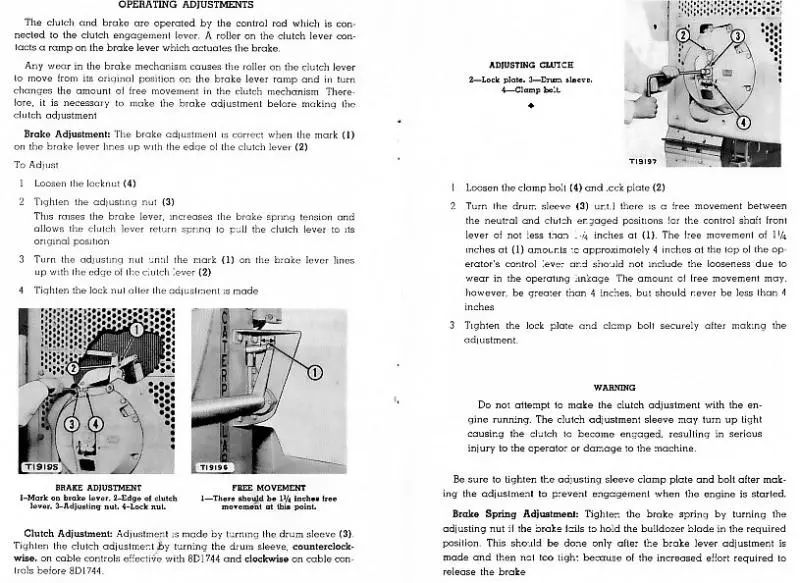

scans below should get you adjusted and back working again.

NOTE____DO NOT ADJUST ANYTHING WITH THE ENGINE RUNNING.

If you do you risk serious injury or worse if you get the clutch adjusted too tight, the cable will reel in and raise the blade.

The lock plate for the clutch adjustment sleeve is the teardrop shaped plate with a retaining bolt at the small end of the tear drop shown at item 3 arrow head in the scan I posted above--this is the clutch adjusting sleeve location--the thing where the larger nut has been welded on that you enquired about above.

Hope this helps as I thought OM posted the Adj. Proceedures earlier. Maybe we have two or three CCU posts going??

Cheers,

Eddie B.

John,

Here is what edb is talking about? “Safety First”

[attachment=22472]Safety Frist_1..jpg[/attachment]

Kelly

Hi John,

scans below should get you adjusted and back working again.

NOTE____DO NOT ADJUST ANYTHING WITH THE ENGINE RUNNING.

If you do you risk serious injury or worse if you get the clutch adjusted too tight, the cable will reel in and raise the blade.

The lock plate for the clutch adjustment sleeve is the teardrop shaped plate with a retaining bolt at the small end of the tear drop shown at item 3 arrow head in the scan I posted above--this is the clutch adjusting sleeve location--the thing where the larger nut has been welded on that you enquired about above.

Hope this helps as I thought OM posted the Adj. Proceedures earlier. Maybe we have two or three CCU posts going??

Cheers,

Eddie B.

[quote="edb"]Hi John,

scans below should get you adjusted and back working again.

NOTE____DO NOT ADJUST ANYTHING WITH THE ENGINE RUNNING.

If you do you risk serious injury or worse if you get the clutch adjusted too tight, the cable will reel in and raise the blade.

The lock plate for the clutch adjustment sleeve is the teardrop shaped plate with a retaining bolt at the small end of the tear drop shown at item 3 arrow head in the scan I posted above--this is the clutch adjusting sleeve location--the thing where the larger nut has been welded on that you enquired about above.

Hope this helps as I thought OM posted the Adj. Proceedures earlier. Maybe we have two or three CCU posts going??

Cheers,

Eddie B.[/quote]

Eddie First and foremost THANKS. Never will I have engine running doing any of this work. Kelly you bring fresh (sadly) realization to a pic worth 1000's words. Thank you, point well taken. My unit is according to OM's thinking a 33E1-up. Do you know if this is before or after the 8D1744 time implemented. The adjustment is opposite between before and after the 8D1744's. A difference of mine,, does have another bolt (two instead of one) than the pic (V mark brake adj) on the lock plate. Close examine of my posted pic shows this but cable is kind of in the way. I'm talking towards top of teardrop shaped plate. I'll repic later today to show exact. Yes OM did send same page as one of yours but again thanks for the expanded education. Per the 'oil wash' procedure, we used to drain, refill with new, run awhile, drain again and refill with new again,,, trying to clean out gunk. Is this similar to cats version ??

The 33E came after the the 8D series.

See if you can get a part number off the lever (with the big spring)

Early unit should be a 4F2935

Changed to a 6F9478 @ 8D6093

Then to 2H3989 on 8D15,607 and the 33E units.

Hi John,

Kelly's pic is not what it seems.

I believe it is taken from a Safety Film produced by Cat, from memory it may have been from either The Gamblers or The Roll Of Drums.

These were staged to demonstrate what could happen. We were shown these at The Dealer as part of our induction as Apprentices back in the early 1960's.

If your front plate has two horizontal lock bolts it maybe an update I do not have in my early literature then if the bolt and nut threads are in good condition and lubed, they should get enough clamping force to hold the clutch adjustment from backing off.

It is unlikely that the teardrop shaped lock would be needed with the double bolt clamp front cover.

I stand to be corrected.

Cheers,

Eddie B.