Just what did you do to the engine during your overhaul? In frame or complete? New oil pump or not? I assume that the pump had to come down to get to all the connecting rod bolts.

Did you prime the oil pump or pressure prime the engine main oil gallery? What kind of assembly lube did you use on the crankshaft?

Got any left over parts?:rip:

I have been into two CAT engines (both of the ones I have had the oil pan off) which had gotten some stray parts into the suction bell of the oil pump. In both cases, it resulted in no oil pressure. Funny thing was the engine lost oil pressure long after it was closed up and returned to service.

The D311 in a grader had no oil pressure when I got it running after we bought it. Had no history on it before we got it other than the previous owner never got it started.............good thing (no oil pressure). It had sucked up a roll pin (one of at least 3 which were left or put into the suction bell of the oil pump when it was assembled. Obviously grinding up a hardened steel pin didn't do the oil pump any good!

The other one was a D333, again in a grader we got as not running but with "everything it will take to fix it". It had experienced a piston failure and the connecting rod had beaten the cylinder sleeve out and damaged the block. When we examined the oil pump, it had ingested a sheetmetal lock tab as used on many bolts inside the oil pan. Again, suction bell and screens were in place and the stray part must have been either put in there or left in there by mistake.

Are you positive your gauge is functioning? i have had gauges go both ways, one showing pressure when there wasn't any, and some showing no pressure when there was.

The oil leak may be your issue, some engines pump all the oil through a cooler before it reaches the engine, may be your pumping the oil out onto the ground. Keep the fuel shut off and crank the engine for no more than 30 seconds at a time if you have an electric starter, allow the starter to cool down between cranks so you don't damage the starter. you should get good oil pressure in that amount of time. use a new gauge just to verify that you have pressure, then diagnose the leak, I would also get the oil level to the full, stopped mark on the dipstick before attempting to start again, 6 gallons may not be enough oil.

I actually disconnected the oil gauge line at the back of the cylinder head and cranked it (governor in OFF setting) and only a drop or two of oil came out--so I've either got a plugged line somewhere, or it's already pumped enough out that it's not sucking any into the pump. I'll buy a few more gallons of oil and add one at a time to get it to the full line and give her another try--like you said. I may have the wife do the cranking so that I can get in there with a light so I can see where all that oil is coming from.

Thanks again!

[quote="rmyram"]Are you positive your gauge is functioning? i have had gauges go both ways, one showing pressure when there wasn't any, and some showing no pressure when there was.

The oil leak may be your issue, some engines pump all the oil through a cooler before it reaches the engine, may be your pumping the oil out onto the ground. Keep the fuel shut off and crank the engine for no more than 30 seconds at a time if you have an electric starter, allow the starter to cool down between cranks so you don't damage the starter. you should get good oil pressure in that amount of time. use a new gauge just to verify that you have pressure, then diagnose the leak, I would also get the oil level to the full, stopped mark on the dipstick before attempting to start again, 6 gallons may not be enough oil.[/quote]

When the block was repaired, did the machine shop vat the block and clean the oil galleries? That metal from the spun bearing would have went into them. I would bet that it went through the oil pump too, did you inspect it according to Cat specs? Did you clean the metal out of your oil cooler?

You can make a quick pressure primer by taking a 2" piece of pipe about 3' long (or an old air tank, etc.) and plumb a hydraulic line on one end with an 1/8" male pipe fitting and screw a 2" shut off valve on the other end. Then weld a 1/4" air fitting onto the side of the pipe under the shut off valve. To use it, screw the hydraulic line into the oil gallery(normally where your oil pressure gauge screw into), open the shut off valve and pour in your oil, close the valve and air it up using regulated air pressure (I used a small regulator at the air fitting) at about 40 psi. I put a small shut off valve on the hydraulic line as well.

You'd be able to pre lube your engine and find that leak without cranking the engine.

Yes, the shop did vat the block and (supposedly) cleaned out the oil galleries. I checked the screens on the oil pump intakes, and there definitely was some metal trapped in them. I cleaned them as well as I could before re-assembling the engine, but didn't use a micrometer to check the pump (it did look good though--no obvious scoring or wear).

I like your suggestion about the pre-oiler. I'll see about putting one together and giving it a try.

Thanks!

P.S. after the bearing spun (before the crank broke) I had good oil pressure when I was cranking engine (didn't realize at that time the bearing had spun--otherwise I wouldn't have cranked it).

[quote="d9gdon"]When the block was repaired, did the machine shop vat the block and clean the oil galleries? That metal from the spun bearing would have went into them. I would bet that it went through the oil pump too, did you inspect it according to Cat specs? Did you clean the metal out of your oil cooler?

You can make a quick pressure primer by taking a 2" piece of pipe about 3' long (or an old air tank, etc.) and plumb a hydraulic line on one end with an 1/8" male pipe fitting and screw a 2" shut off valve on the other end. Then weld a 1/4" air fitting onto the side of the pipe under the shut off valve. To use it, screw the hydraulic line into the oil gallery(normally where your oil pressure gauge screw into), open the shut off valve and pour in your oil, close the valve and air it up using regulated air pressure (I used a small regulator at the air fitting) at about 40 psi. I put a small shut off valve on the hydraulic line as well.

You'd be able to pre lube your engine and find that leak without cranking the engine.[/quote]

I wonder if a piece of debris is stuck in the main oil pump pressure relief valve, or was a core plug left out of the end of the main oil gallery after cleaning out? Drop the oil pan, strip and check the main oil pump relief valve. Drop the oil pump and put an air line to the main port into the block and see if the air comes down through the timing case or between the flywheel housing and the back of the block.

Hi jgbmo,

cannot add any to suggestions so far for low oil pressure except to say that for a completely dry engine a lot of oil volume is lost wetting the inner surfaces of the engine as well as oil galleries, filters etc.

Cold oil is also lost as it is reluctant to flow back to the sump until warm--the main reason to check oil level when the unit is at operating temperature.

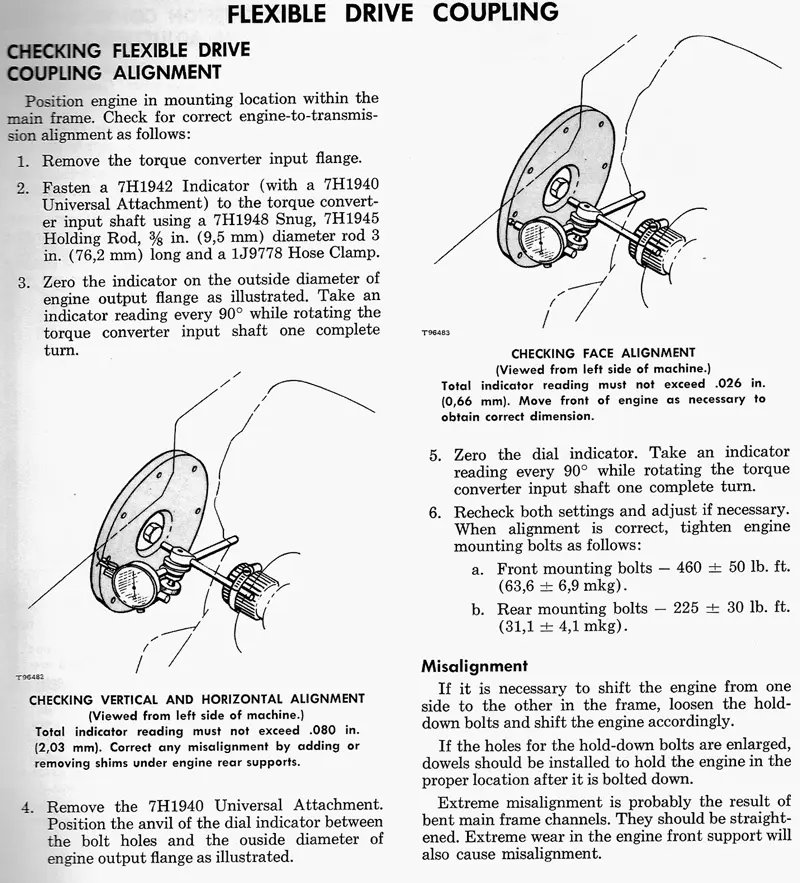

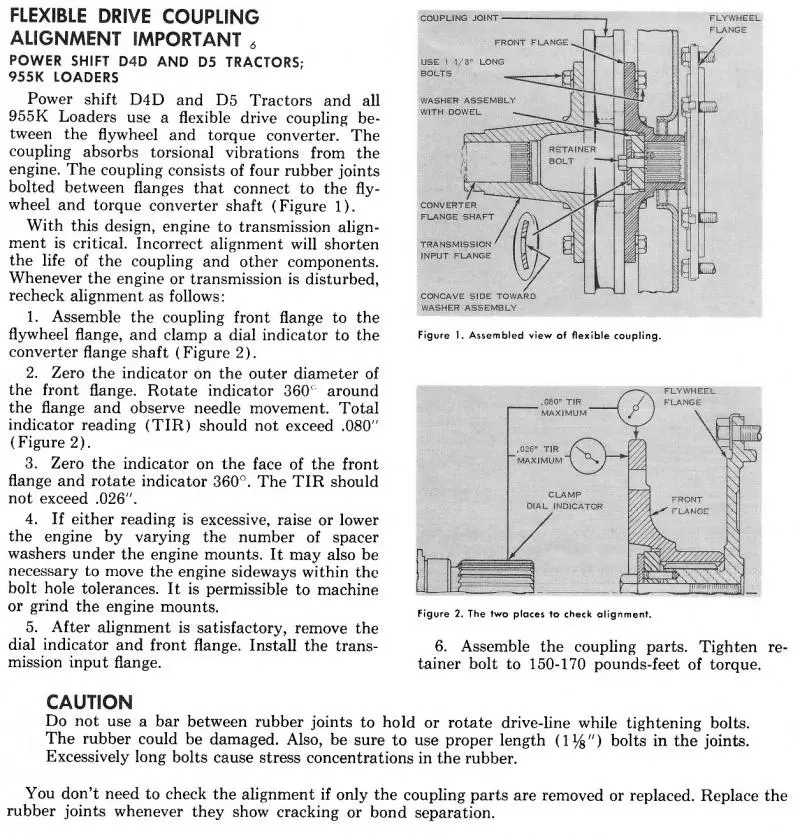

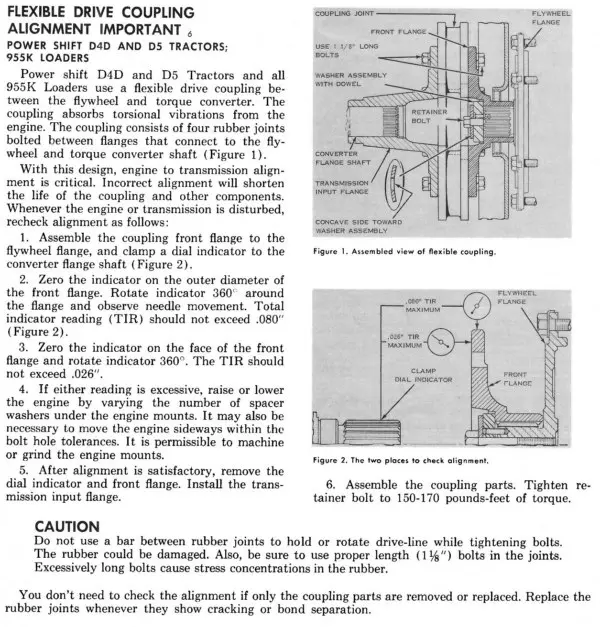

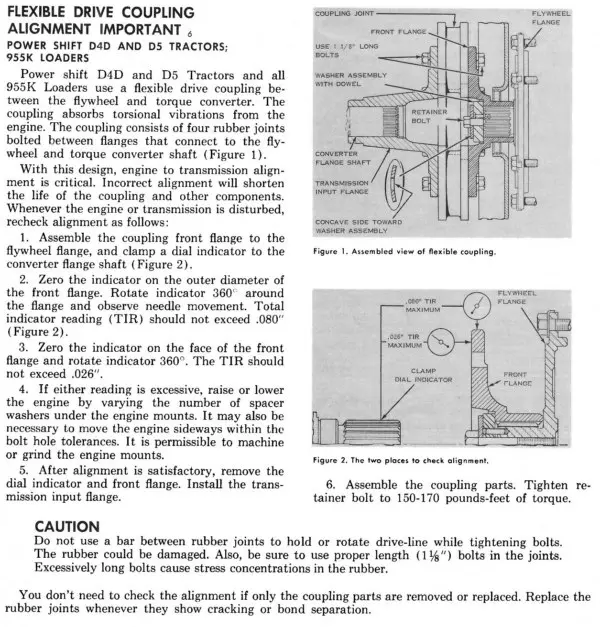

Any machine with couplings needs to be in correct alignment as detailed in the attached scans below. Misalignment causes failed rubbers and broken cranks and or failed main bearings in this style of drive.

Hope this helps,

Eddie B.

My 955K is sitting where it broke down about a year and a half ago, and because winter returned right after I tried to start it (after rebuilding), it's too cold to verify this, but I think I found my leak. I was looking around the area on the block behind the hydraulic oil cooler and I spotted a large opening that appears to be a spot where I missed putting in a plug. The weather is supposed to improve tomorrow, so assuming it's not raining or snowing, I'll use some extensions and a 9/16" socket to screw a plug into that spot, then top off the oil (I think most of it's on the ground), and try cranking her up. If that fixes it, I'll get oil pressure as soon as she starts cranking. Keeping my fingers crossed! If I'm right, it'll be a dumba$$ mistake, but one I'll gladly take credit for.

Thanks to everyone who offered help with this machine!