Yes there is a radius between the flange and the begining of the threads where the sealing washer is accomodated. Can't find the pictures I was looking for but maybe this will help.

Hi Team,

If you are asking if the pre-comb thread in the head starts as a step down--counterbore-- below the pre-comb gasket seal face then I believe--from memory--that the thread can be counterbored below the pre-comb gasket seat face on some heads and not on others.

Early on engines had copper gaskets and later on there was an update to soft ingot iron gaskets on all screw in pre-combs.

Also the head castings have excess metal in some areas that when a maching process is carried out, such as spot facing the pre-comb gasket seat area, a lip can be formed due to the extra width and height of the seat area of the raw casting--the seat then appears to be counter-bored into the head.

On some seat areas the cutter will break out past the faced area and in some other parts --arcs of the same seat-- will be left as an uncut section of casting.

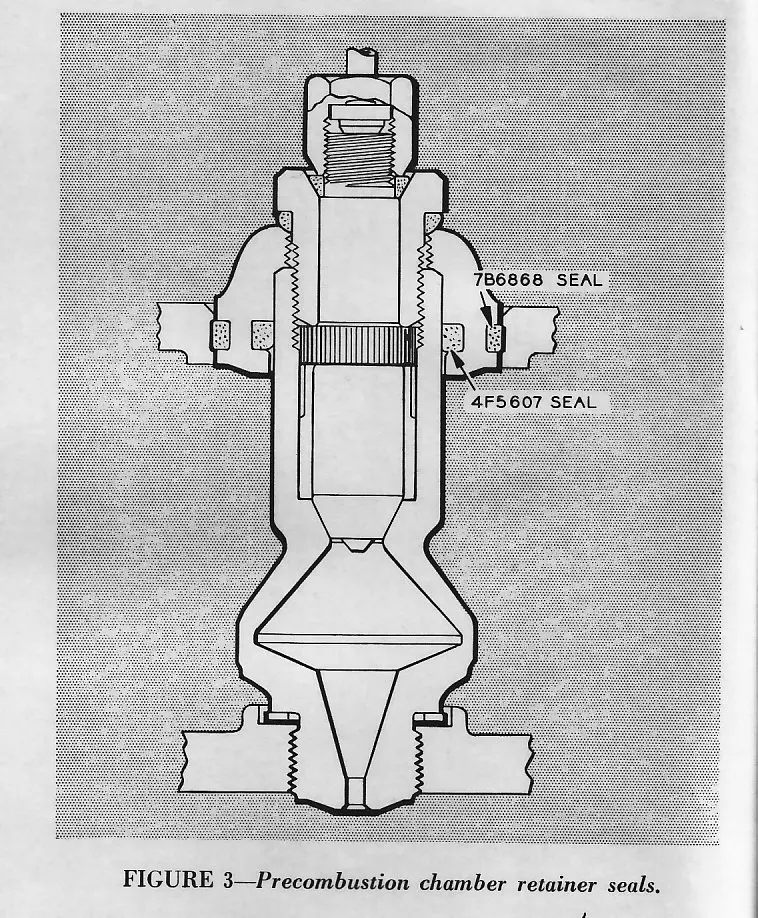

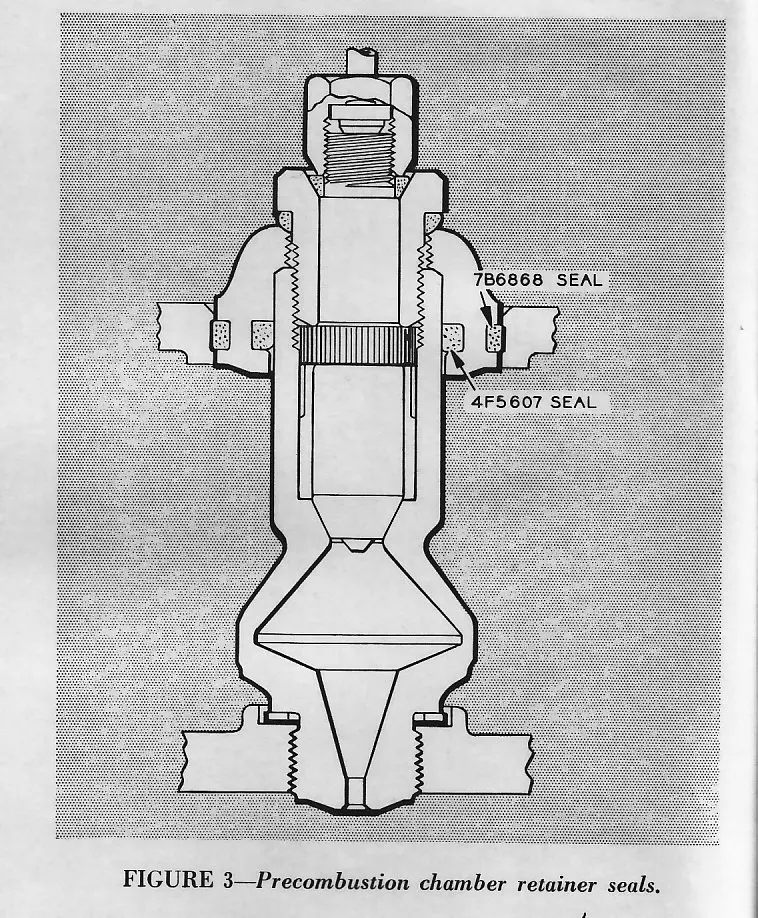

Scan below from a Sales Brochure maybe shows what OM was trying to describe on the pre-comb body.

Cheers,

Eddie B.

[quote="edb"]

Also the head castings have excess metal in some areas that when a maching process is carried out, such as spot facing the pre-comb gasket seat area, a lip can be formed due to the extra width and height of the seat area of the raw casting--the seat then appears to be counter-bored into the head.

Cheers,

Eddie B.[/quote]

Yes, the seat area in the head appears counter bored into the casting about an eighth of an inch deep. Your second picture shows that recessed seat where the steel (or iron) washer is supposed to seal. It also shows that the threads do not start immediately at the seat. That was the second question that appears to have been answered. I have seen the seat area on a D7E that was not counter bored. From memory it appeared to be a raised cast area that had a seat cut into it.

I was trying to make sure that there was not an old washer still in the seat area.

Now, I need to know how to dress that seat area. Will I need to take it to a machine shop to face it? I can see a small chip out of #3 that I don't like and all of them have carbon deposits.

Yes, appears you will need machine shop services to spot face the chamber seat.

If you have access, head off, measure/compare the depth to the seat to tell if a sealing washer is still in place.

My machine shop said $15 per hole to face them. It still looks to me like there is a washer in each one. They all look the same though. What I'm afraid of is that they're made from copper and they're formed into the recess. That's what it looks like. One of the holes had two washers in it. I've never seen them so messed up, they're a lot thinner than what's on a D7E.

The sealing washers I got new today from Cat(5B3265) look like they're made from copper. I checked them with a magnet and they're non ferrous.

Maybe the machine shop has more experience with them and can tell when they get to them. I think I'll ask them how much to pressure test it tomorrow. I don't want to have to pull it again. It's different when you can see down in there, like on a D4 if one's leaking. I'll have to get my chambers all cleaned up and installed after they face the seat.

BTW, what is the correct quadrant for glow plug alignment? I don't have the D315 manual. I have some thinner and thicker washers ordered that will be here tomorrow.

Here is the glow plug indexing procedure:

Thanks, that sure beats trial and error.

Here's some pics:

[attachment=16333]Photo035[1].jpg[/attachment][attachment=16334]Photo036[1].jpg[/attachment][attachment=16335]Photo037[1].jpg[/attachment]

Yup, confirms what you've been saying.....needs spot facing, otherwise looks normal. If there are any washer/seals imbeded in there the machine shop will soon find out.

Hi Don,

looks normal, as OM said, light might be playing tricks. Sometimes the copper washer particles embed into the iron and makes it look like the washer is still there.

Now we have the extra info that you have pre-comb style chambers, it is probable that 2 washers were fitted so as to "TIME" the glow plug holes to suit the chart OM supplied.

Cheers,

Eddie B.