maybe this will help: http://www.oldengine.org/members/diesel/Eisemann/MagData.htm

mike, this is off topic of ur disk question which i think is ur problem. but anyway u gotta watch those old Eisemanns, my experience is that most out there has old weak coils. my Eisemann 2 cylinder pony mag will start the engine but the coil goes bad after about a minute, stalls and not enough running time to start the diesel. wait a hour and half and it'll start again and run less than a minute. i talked to a mag guy and he said get a aftermarket wico mag or put about 500.00 into the Eisemann rebuild. good luck.

ps i'm going to put some other mags on ebay, some have spark and some don't, i'm going to list saying; " exact condition unknown because it can have spark by hand but when mounted on engine it may not run as it should."

mike, this is off topic of ur disk question which i think is ur problem. but anyway u gotta watch those old Eisemanns, my experience is that most out there has old weak coils. my Eisemann 2 cylinder pony mag will start the engine but the coil goes bad after about a minute, stalls and not enough running time to start the diesel. wait a hour and half and it'll start again and run less than a minute. i talked to a mag guy and he said get a aftermarket wico mag or put about 500.00 into the Eisemann rebuild. good luck.

ps i'm going to put some other mags on ebay, some have spark and some don't, i'm going to list saying; " exact condition unknown because it can have spark by hand but when mounted on engine it may not run as it should."

maybe this will help: http://www.oldengine.org/members/diesel/Eisemann/MagData.htm

Hi Mike,

from memory the big gear should have both an L and an R on it for left or right hand rotations.

This timing is not super critical for the best spark.

That having been said, this timing puts the brass contact segment in the optimum position for the brush to pickup the spark in the range of full advance to full retard.

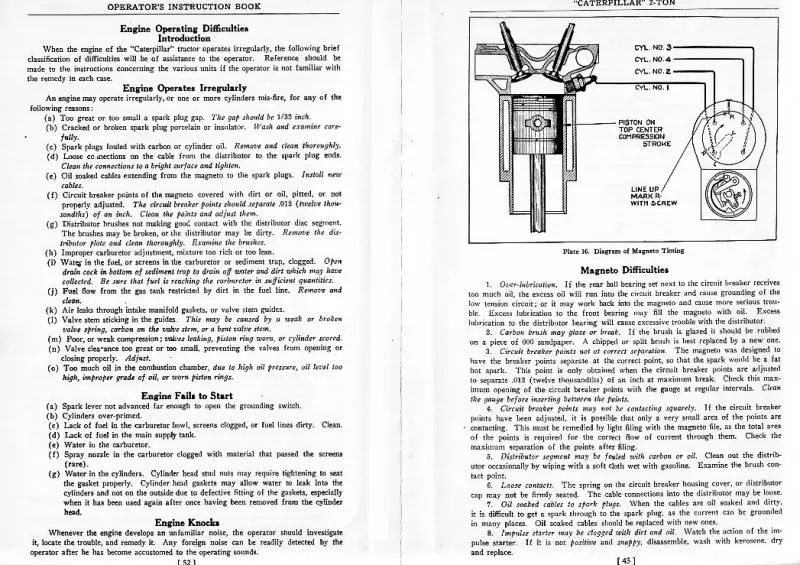

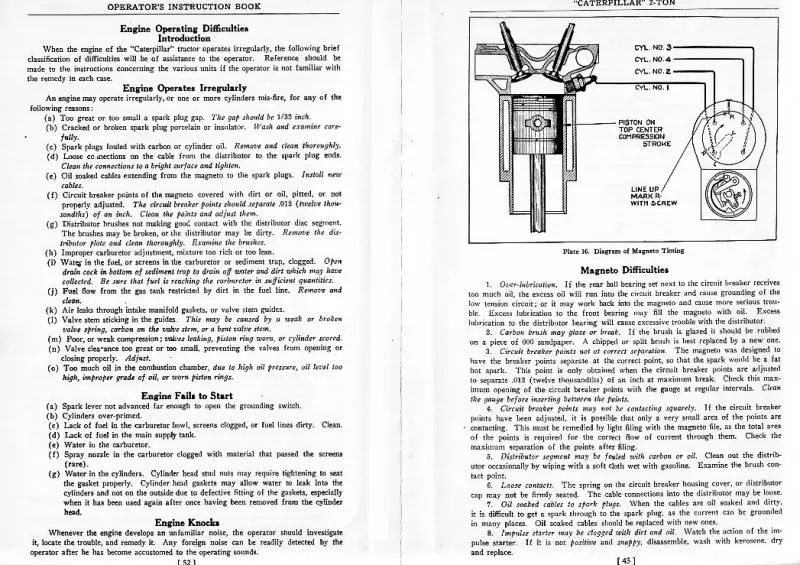

The scan below from the 2Ton OMI should explain and show the timing positions of the dots, letters etc.

Have checked the left overs in the shed and can see that the marks on the big gear are very faint and you need good sunlight to see them--maybe a magnifying glass.

On the right scanned page is a good list of maggie problems--this also goes to the next page of your OMI on disc I sent you years ago.

Another thing if you need to tow it, your impulse coupling may not have enough end clearance and cannot wind up and release cleanly for a good spark---over oiling the coupling causes tardy op too.

Other factors can be establishing the correct amount of choke and throttle stting for a good start from cold or hot, idiosyncrasies of machines vary--maybe a tight inlet valve lash, air leak in inlet track etc. can be factors to cause hard starting along with many other little problems/deficiencies.

Hope this helps.

Cheers,

Eddie B.

Hi Mike,

from memory the big gear should have both an L and an R on it for left or right hand rotations.

This timing is not super critical for the best spark.

That having been said, this timing puts the brass contact segment in the optimum position for the brush to pickup the spark in the range of full advance to full retard.

The scan below from the 2Ton OMI should explain and show the timing positions of the dots, letters etc.

Have checked the left overs in the shed and can see that the marks on the big gear are very faint and you need good sunlight to see them--maybe a magnifying glass.

On the right scanned page is a good list of maggie problems--this also goes to the next page of your OMI on disc I sent you years ago.

Another thing if you need to tow it, your impulse coupling may not have enough end clearance and cannot wind up and release cleanly for a good spark---over oiling the coupling causes tardy op too.

Other factors can be establishing the correct amount of choke and throttle stting for a good start from cold or hot, idiosyncrasies of machines vary--maybe a tight inlet valve lash, air leak in inlet track etc. can be factors to cause hard starting along with many other little problems/deficiencies.

Hope this helps.

Cheers,

Eddie B.

Hi Mike,

MMmmm, good observation there Mike, I have had points before that were tight on their pivot post. They would rattle closed and bounce of the cam and stay partly open, as you are finding.

I dismantled the points and polished the post with some super fine worn out wet or dry paper. Lubed the points fibre with CRC and had success.

Keep at it and you will soon be the Eisemann expert here.

Another thing to check is that the return spring assembly has had the second leaf fitted correctly--one end is bent back slighly to stop it digging into the main leaf when in the tensioned condition. From memory if it is fitted on the wrong side of the main leaf or back to front it can cause detensioning or binding of the main leaf.

Cheers,

Eddie B

[quote="edb"]Hi Mike,

from memory the big gear should have both an L and an R on it for left or right hand rotations.

This timing is not super critical for the best spark.

That having been said, this timing puts the brass contact segment in the optimum position for the brush to pickup the spark in the range of full advance to full retard.

The scan below from the 2Ton OMI should explain and show the timing positions of the dots, letters etc.

Have checked the left overs in the shed and can see that the marks on the big gear are very faint and you need good sunlight to see them--maybe a magnifying glass.

On the right scanned page is a good list of maggie problems--this also goes to the next page of your OMI on disc I sent you years ago.

Another thing if you need to tow it, your impulse coupling may not have enough end clearance and cannot wind up and release cleanly for a good spark---over oiling the coupling causes tardy op too.

Other factors can be establishing the correct amount of choke and throttle stting for a good start from cold or hot, idiosyncrasies of machines vary--maybe a tight inlet valve lash, air leak in inlet track etc. can be factors to cause hard starting along with many other little problems/deficiencies.

Hope this helps.

Cheers,

Eddie B.[/quote]

Thanks for the scans, my large gear has both a R and L stamped on it, my concern is the smaller distributor disc also has a R clearly stamped in it, but they are about 150 degrees apart from each other, and with only 3 screws to mount those distributor discs onto the gear, there is no opportunity to adjust that situation. This self opening of the points has me puzzled right now, so I'll report back in awhile if I find a cause, because unless I'm mistaken the points should be closed for about 340 degrees of the armatures rotation, opening only briefly for about 10 degrees each time they hit both timing blocks on the outer timing ring, or have I got that wrong?

thanks for your help

Mike

Hi Mike,

do not sweat the gear/ segment timing marks too much, the critical thing is the segment relationship as shown in the scan.

If you set the points just opening or just against the block as per the scan and, with the advance and retard rotation of the housing with the blocks in, set at halfway, then the pickup brush should align to the middle of the brass distributor segment, also as shoen in the scan.

Cheers,

Eddie B.